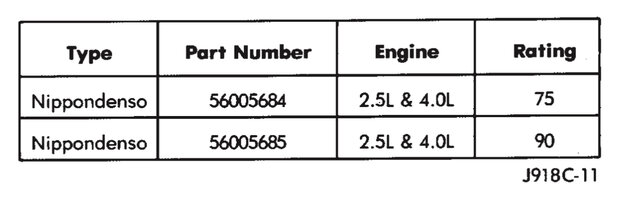

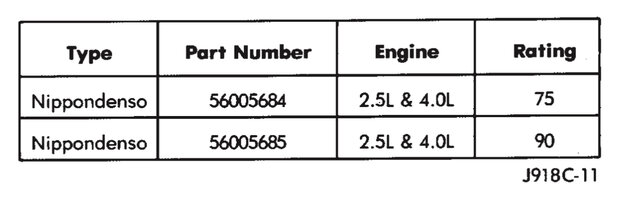

The ‘91-‘95 YJs came with either a 75 amp or 90 amp alternator. Like the majority of those YJs, mine came with the 75A. The way to tell is by looking at the Nippondenso sticker on it: 56005684 is 75A, and 56005685 is 90A.

I never had any problems with the 75A, but I also have never winched. I did notice that sometimes the voltmeter on the dash would dip some when I’d turn on the heater, and that could be due to wiring, old gauge, or the alternator. I do plan on adding a winch that I will use infrequently, but sometimes, so I decided to swap to the 90A. There is a common 1998 Durango 5.9L 136A alternator upgrade that people on other forums mention doing, and there’s nothing wrong with that if you need/want it, however, the stock YJ wiring is only safe with the factory YJ alternator options, aka the 75A or the 90A. It isn’t meant for 136A. So people end up adding their own wiring, their own maxi fuse, etc. If you need it that’s fine, I do not and don’t feel like adding all that for something I don’t need. So I decided to do the bare minimum upgrade that was easily to install with no extra work at all. I should also mention that on the Durangos, they used 4 AWG wiring for that 136A alternator, which goes to a supposedly 140A fusible link (fuse perhaps?), and on the YJ we have 8 AWG that splits into 2 10 AWG wires and runs through a 60A and 40A fuse. That is a significant difference. The TJ uses a 6 AWG cable (probably realized what they should have used on the YJ) with a short piece of 10 AWG as a fusible link.

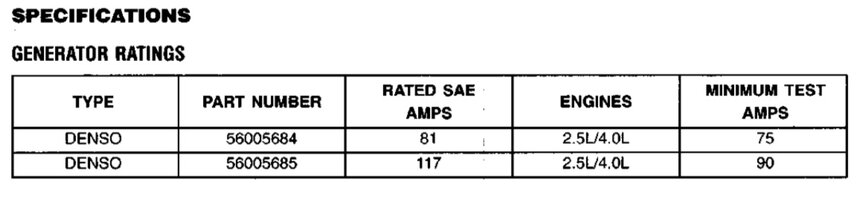

Something to also understand is the way the alternators are rated is a bit misleading.

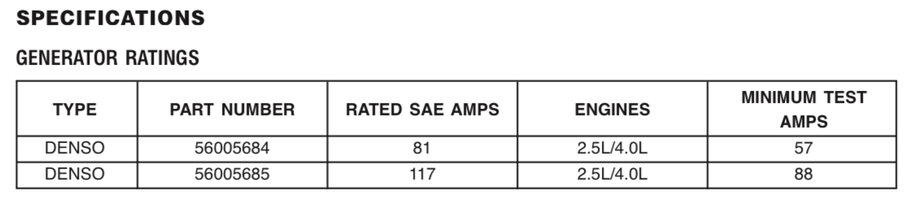

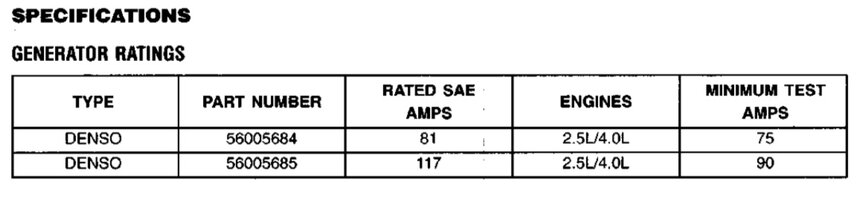

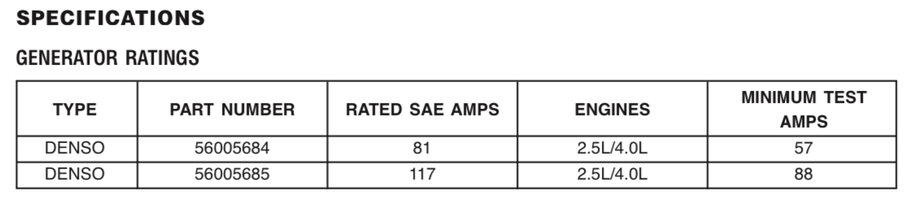

The YJ and 97-98 TJ utilize the exact same 2 alternators, 56005684 & 56005685. However, on window stickers, in parts stores, etc, they are mentioned differently. The TJ alternators are mostly called 81A and 117A while the YJ are the aforementioned 75A and 90A. I did some digging in the factory service manual and partly found out why.

YJ:

97 TJ:

98 TJ:

So the YJ has only the “rating” column and it lists 75 & 90 amps. The 97 TJ expands and breaks into minimum test amps and rated SAE amps. My guess is that the “rating” on the YJ chart is the minimum test amps, and at the time of the YJ they simply didn’t list the SAE rated amps.

The 98 TJ chart is a bit weird because the lower rated alternator drops its minimum way down to 57 amps (maybe a typo?) and the higher rated alternator is down to 88 amp minimum, which is very close to 90.

My thinking is the part numbers are the same and the PCM manages them the same whether it’s a YJ or a TJ. Call it what you want, but I like to think I have the “117 amp alternator” that TJ folk refer to. So I like to think I’m not far off from the 136A from the Durango anyway.

Enough about the details. I installed it this afternoon and we’ll see how it does.

It came in a Mopar box and the sticker says it was made in February 1999. Pretty old, but it’s great shape from storage so should be fine.

Some comparison photos, old vs new:

Installed: