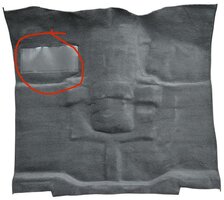

I decided to remove the shifters so the carpet will lay flat and I can cut it more accurately to fit under the boot. I looked up how to remove the shifter. It’s great what the FSM and a couple online videos can show you in 15 minutes!

Inside the shift tower was this ugly thing, which I suppose is a decomposing bushing.

I found a Crown part that looks like it, so hopefully that will fit the bill!

Inside the shift tower was this ugly thing, which I suppose is a decomposing bushing.

I found a Crown part that looks like it, so hopefully that will fit the bill!