That sounds about right. Those shims from OME springs are making the pinion too high, but once you add the tcase drop from them you should be good to go.Yeah those large shims came out, so the pinion is much flatter now. Angle finder says about 9 degree slope, if I'm using it right.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'95 Sahara, 1st YJ

- Thread starter TRevs

- Start date

I’ve now brought the suspension where I intended it to be and I’m getting some mild-moderate driveline vibrations. It’s on the 2.5” springs (skyjacker front, OME rear), stock-size shackles with the OME transfer case drop kit installed. There are things shims under the rear axle which I assume are the 2° shims that are often used with the OME springs.

My driveline angles could be excessive but they don’t seem extreme.

I’m getting virtually equal slopes on the pinion and transfer case (7° from horizontal) and 22° slope on the driveshaft. That means 15° on each U-joint, which may be the problem, although I was expecting the T-case drop + shim to work without vibes on 2.5” springs.

My driveline angles could be excessive but they don’t seem extreme.

I’m getting virtually equal slopes on the pinion and transfer case (7° from horizontal) and 22° slope on the driveshaft. That means 15° on each U-joint, which may be the problem, although I was expecting the T-case drop + shim to work without vibes on 2.5” springs.

This is all new to me; the rear driveshaft on my LJ is much longer so I don’t have vibes on 2.5” springs.

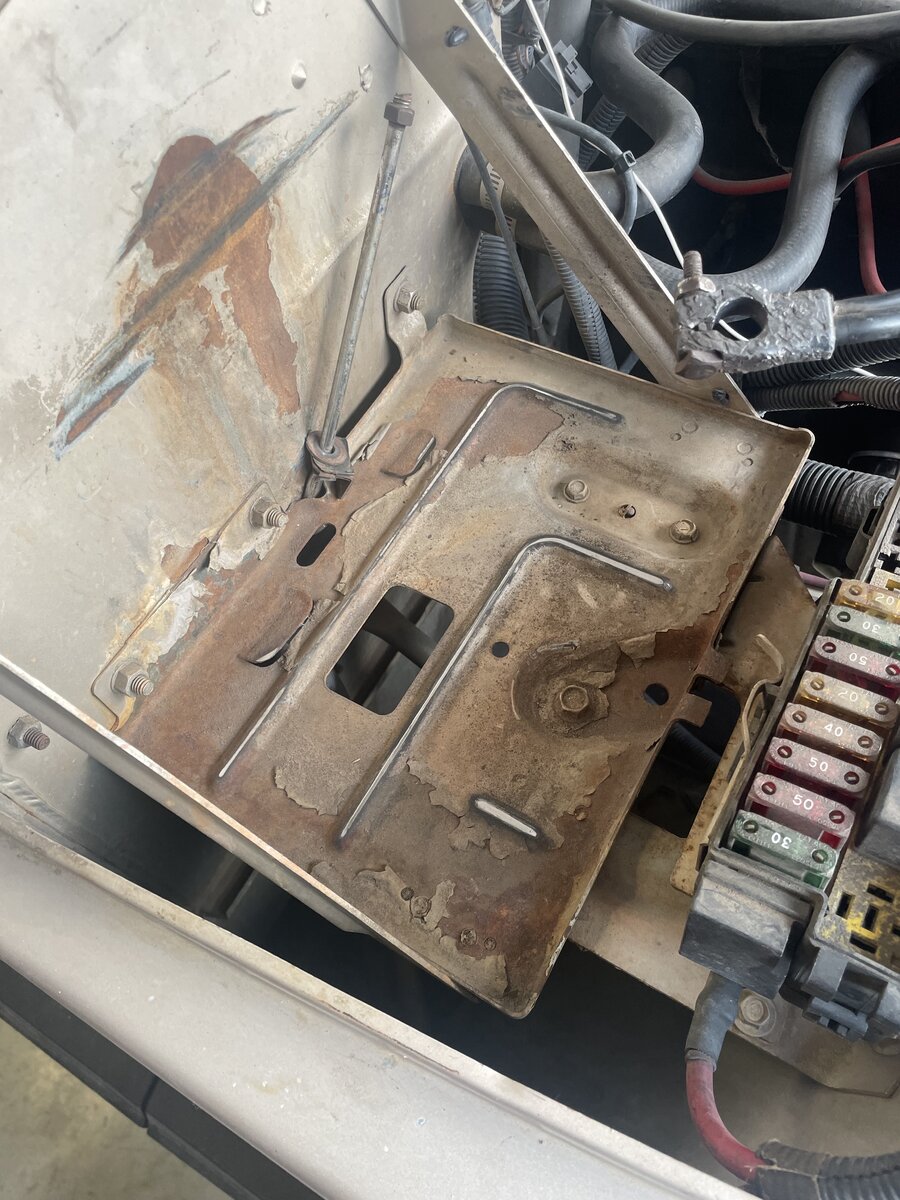

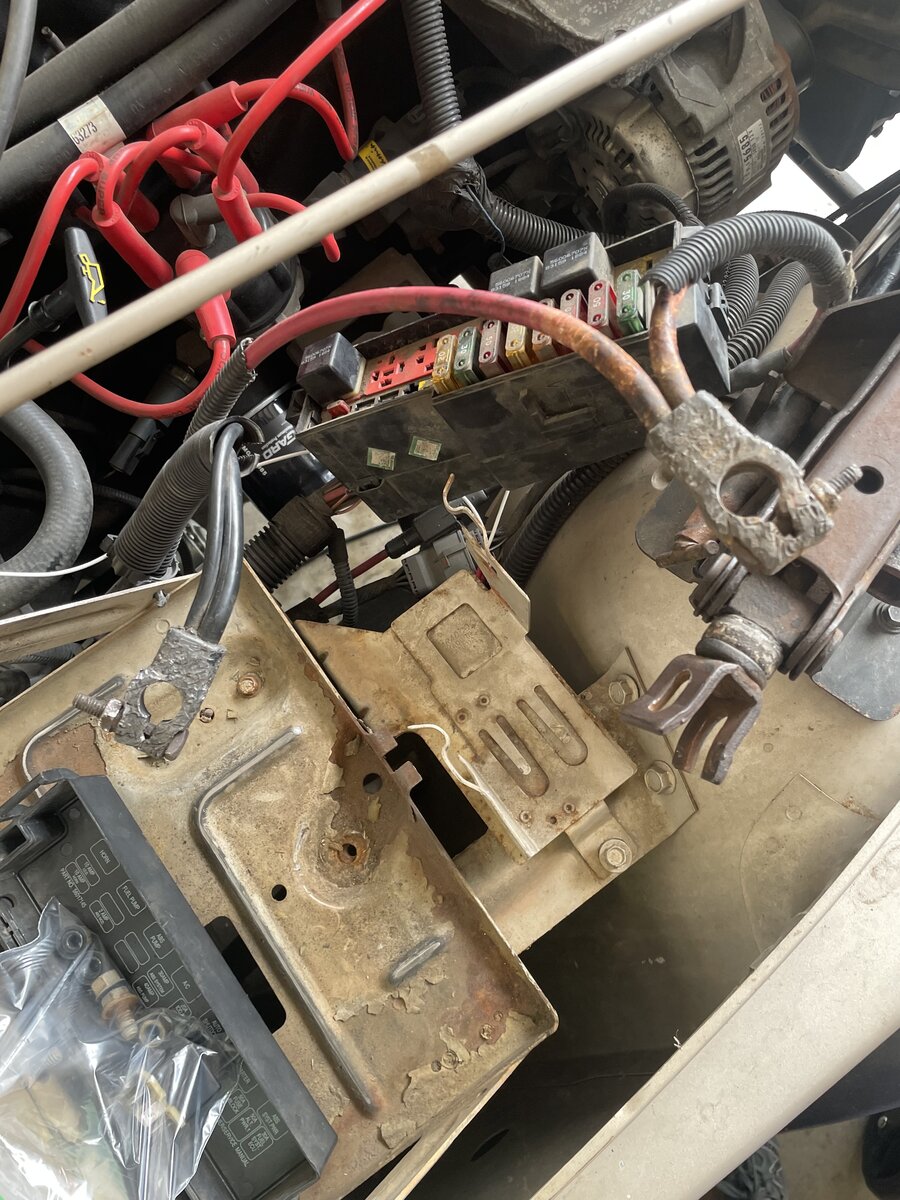

Next I wanted to tackle the battery tray. There's no hold down, so it appears the battery has bee sliding all over and damaged the paint on the firewall, leading to early rust. The tray itself was pretty rusty as well. The PDC has to be removed to get the tray out.

I tried a combination of brass wire brush, sand paper, and Rustoleum Gel Rust Remover. I got the pieces satisfactorily rust-free. The photos don't show the final state of rust removal, but give a good idea.

Next is the exhaust system replacement. The manifold and muffler have cracks and leaks, and the entire system is rusted.

I ordered the complete kit from RockAuto and started disassembly.

There are two essentials for this job: 1) the FSM available on this site, and 2):

The power steering pump and bracket need to come off (hint: there's a hidden third bolt under the pump itself into the intake manifold).

The bolts underneath the manifold were a bit tricky to get to, but the rear 2 or 3 were accessible with a ratcheting wrench, and I was able to pass a 1/4" drive socket/extension between the pipes to get to the other bolts. I'd sprayed Liquid Wrench on a few times in the preceding days, and these bolts thankfully were not put on with a lot of torque. Probably less than 30 ft. lbs. to remove.

I ordered the complete kit from RockAuto and started disassembly.

There are two essentials for this job: 1) the FSM available on this site, and 2):

The power steering pump and bracket need to come off (hint: there's a hidden third bolt under the pump itself into the intake manifold).

The bolts underneath the manifold were a bit tricky to get to, but the rear 2 or 3 were accessible with a ratcheting wrench, and I was able to pass a 1/4" drive socket/extension between the pipes to get to the other bolts. I'd sprayed Liquid Wrench on a few times in the preceding days, and these bolts thankfully were not put on with a lot of torque. Probably less than 30 ft. lbs. to remove.

It's pretty cool to see the side of the engine exposed. I'll loosen up the coolant drain bolt while I have easy access so it's not hard to get off when I flush the rusty "coolant."

There's a fair coating of oily sludge on the intake of each cylinder. That'll take awhile to clean.

There's a fair coating of oily sludge on the intake of each cylinder. That'll take awhile to clean.

The bolt holding the two-piece hanger on the tail pipe was rusted and broke off, so I drilled it out and used new hardware.

The bolt/post holding the torque arm(?) of the transmission mount was rusted so I got some stainless hardware and rigged a replacement while I was under there.

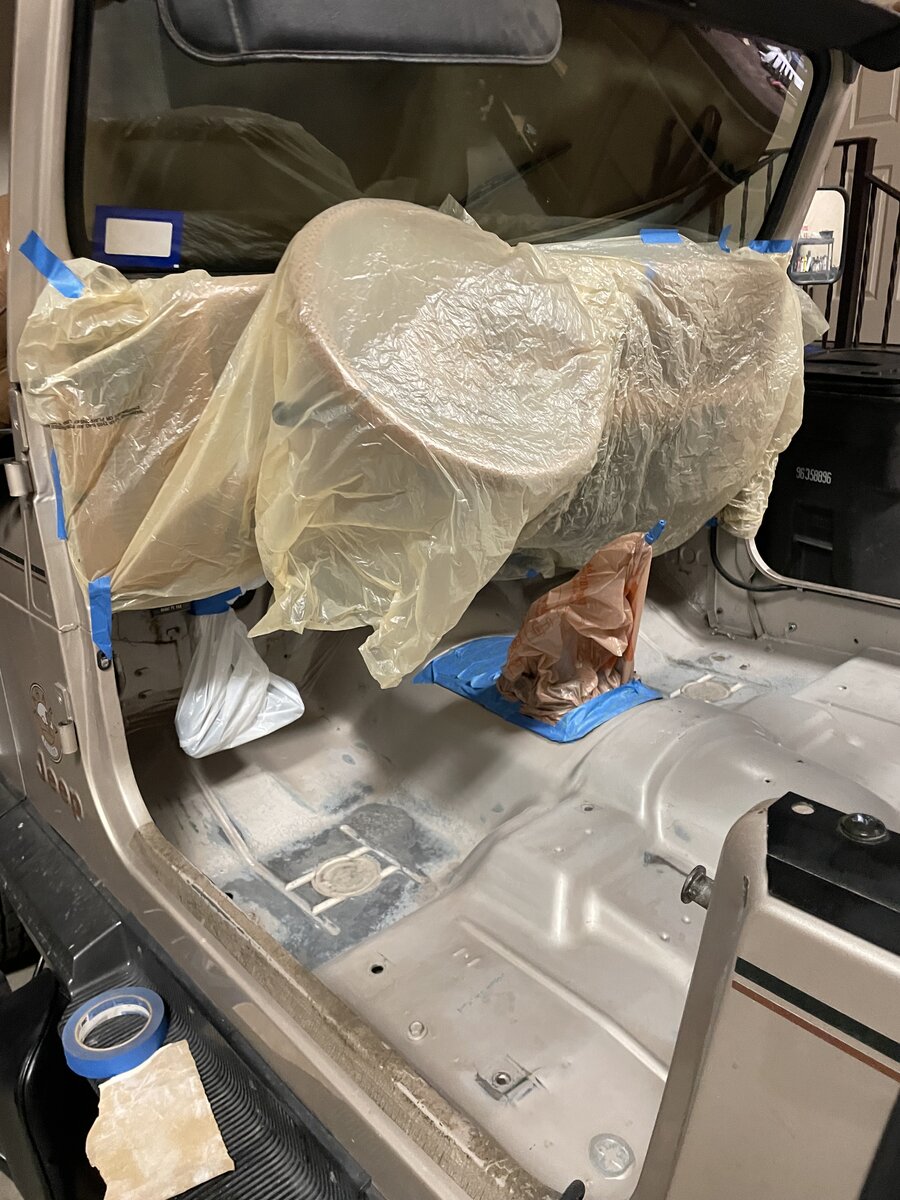

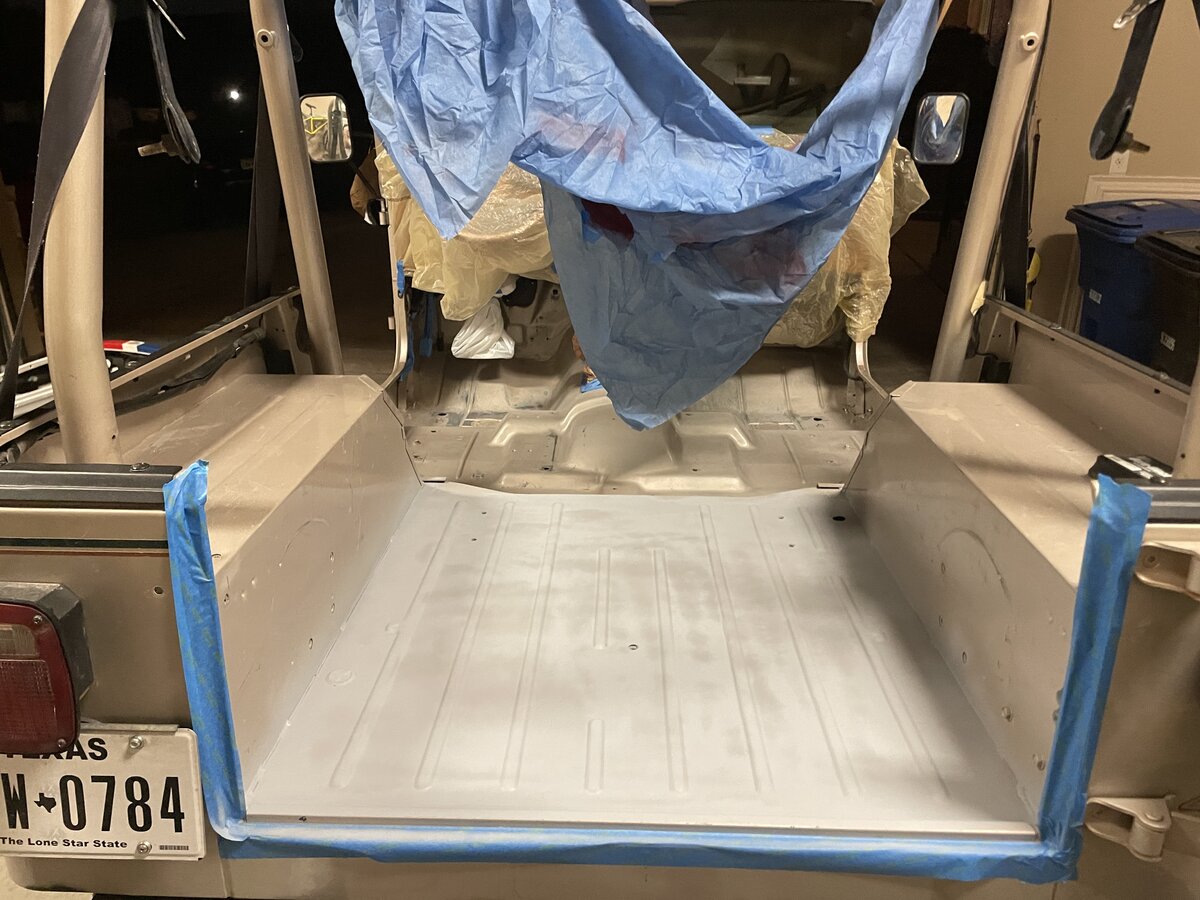

I bought carpet from Stock Interiors but before I install it I wanted to spruce up the interior of the tub. The paint is scratched and scuffed, with some mild surface rust. I want a good layer of paint on there to protect the metal from the friction of the carpet.

I snapped the T40 bit on one of the roll bar bolts, so I'm stuck until I can get to Lowe's for a warranty return.

ACKyj

Member

Any additional pics of what you did here to improvise? I have the same issue with my '95 and the cat rubs on the skid plate and makes a horrendous rattle. Following your thread, keep up the good work, love that jeep!The bolt/post holding the torque arm(?) of the transmission mount was rusted so I got some stainless hardware and rigged a replacement while I was under there.

View attachment 120860

I didn't bother searching for that stud; I just got a bolt at ACE of the same length and thickness. I happened to have a metal sleeve sitting around that fit inside the rubber bushings, then I added a washer and locked two nuts to hold them on. Another washer and a nylock nut on the bottom under the skid plate.Any additional pics of what you did here to improvise? I have the same issue with my '95 and the cat rubs on the skid plate and makes a horrendous rattle. Following your thread, keep up the good work, love that jeep!

I'll try to get some additional photos soon.

I gave up on removing the roll bar prior to installing the carpet. I bent and broke multiple T45 bits, used a lot of heat from a quality Milwaukee heat gun, used a ratchet with cheater bar, and a Milwaukee impact...... still couldn't break free 6 of the bolts. I may ask a friend to weld on nuts eventually, but I have to get the Jeep back in service, so I proceeded with the prep/prime/paint of the floor pan.

Rust removal, and primer:

Rust removal, and primer:

I had a local paint shop mix up a pint of the factory paint color ("Light Pearlstone") and used a paint gun for the first time. The gun I borrowed was too small for this but it was good practice, and I was using a single stage 1K paint. It will go under carpet so it doesn't need to look great. I thought the color match was pretty darn good!