Long post of progress updates. Starting to make some more headway, but naturally, with a few hangups along the way.

I still have some driveline vibes, but I haven’t had a chance to really weigh down the rear yet. I have no rear bumper at the moment, and I haven’t even filled the tank up yet. Thinking about the tank got me thinking about an option: Warn fuel tank skid. I bought one 5 years ago, but it didn’t work out because I was going to use an MTS fuel tank, which is a differently shaped tank than stock. The MTS really doesn’t work on anything besides the MTS tank skid, which is built by Warrior products. So to install that tank, I went with the Warrior skid. I returned the Warn at the time (Amazon purchase).

I didn’t like the lack of a slosh box in the MTS tank, so when I had the tank out for some other reason (to fix the hose on the aftermarket fuel pumps that is known to bust), I went back to the stock tank and sold off the MTS tank and skid. I reinstalled the stock tank with the stock skid.

So now I’m totally back to stock. My skid was rusty and I wanted to add weight to the rear anyways, so I ordered up a Warn skid again, part 66550. I received it yesterday and installed it last night/this morning. Overall it’s a nice product.

Fitment was good, the straps were essentially too short but I just barely got them hooked up and threaded a few turns each. It’ll definitely ride. There were 3 different OEM skid plate part numbers, as well as like 10 plastic tank part numbers, so I imagine there may be some fitment variances and this skid is advertised to fit all 87-95, so I’m not really surprised if it’s not 100% perfect. It did bolt up perfectly to the frame though. Very nice and square.

As my weight varies as I experiment with different things, I wanted to make sure my leaf springs could actually flex at the shackles properly. The stock rubber bushings are okay, but they tend to twist and retain torsion forces which eventually rips them apart. I installed some Energy Suspension poly bushings with their super tacky grease and now the shackles are super smooth. They should stay quiet since that grease is ridiculously sticky and will never drip off. I ordered a front shackle kit to match now so the whole suspension can always equalize better than with rubber.

While the tank was out, it was time to look at the exhaust, since I had to disassemble half of the exhaust to clear the tank coming down anyways.

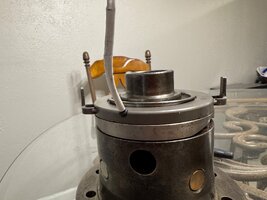

I took the cat off and measured from the alignment nub to the end of the downpipe. It was just a hair over 1.5”. I measured on the cat from where it necks down (where the downpipe would essentially bottom out) and marked a little less than 1.5” forward of the necking so that I knew my max amount of anti rotation slot to grind. This would allow for absolute maximum adjustability. Some quick work with the 4.5” grinding disc and some files to clean it up and I had the biggest slot I could utilize.

Once I got the tank back in this morning, I started to reassemble the exhaust. It is now hanging from all hangers and just needs to be tightened up at all joints to eliminate slop and make sure it clears everything.

Don’t want to be too optimistic, but I think I have FINALLY fixed my issue. Even with heat expansion, that gap seems so big that I think I have plenty of clearance. Disregard the weird slant in the pipe, that is because things are sagging while the clamps are loose. Once I get it all snugged up, it should look pretty normal.

I still also have the Magnaflow exhaust, if that ended up being a better option. Now that I’ve slid the cat so far forward, I could potentially fine tune the Magnaflow and get it installed. I liked the design of it better, but the sound of Banks better, so gonna roll with banks for now. The funny thing is, with the cat moved so far forward, I bet the Borla would work now…lol. Maybe someday I’ll try it out again, but I’ll be buying it from Summit if I do that again. I sure did like the way it sounded.

Now for bumpers. The Smittybilt rear still isn’t working out. I don’t remember how much I’ve talked about it here because I’ve talked about it privately with several - thanks to anyone who listens to my bitching. It doesn’t bolt up properly due to lower frame tie in tabs which are really what provide any strength the bumper has. Without those tabs the rear crossmember would rip right off of frame in a recovery. Which I may not ever do, but I probably will do some trails in the near future, and so I want things to work. Anyways, the Smittybilt will not sit flush against the crossmember because of the odd shape of these tabs. Not sure if it’s too much welding slag or what, but it’s definitely no good.

When you go to put in the 8 crossmember bolts, first off, they don’t all go in. The ones that you can get in will eventually get tight (even though they’re not fully threaded in. Some of them thread in normally but as they pull the bumper up to the crossmember harder, they cause my frame to start squeaking like it’s under a bunch of stress. I’m about done with this thing.

In the spirit of all things Warn, I ordered a rear bumper which is back ordered but due for production on August 18. Warn makes a good bumper and I sure have strong hopes that this one will fit right. So far every other bumper I’ve tried has fit fine, and it’s only been the most recent tow hitch and the latest Smitty that I’ve tried that didn’t work.

Since I’m going with Warn, I put the front back to the Warn also. That is asinine since I just finally finished the stock front, but it is what it is. I wanted matching looks since I have the matching front already. So that is back to how it was before and just waiting on the rear to show up. At least it looks good…and it fits perfectly.

One thing I’m working through is the Tom Wood’s shaft. It is leaking. I can’t tell if it’s coming out of the end of the slip yoke by the u-joint, or if it’s a sealing issue. I intend to figure it out and then work it out with TW, but I don’t want to deal with it yet. I FINALLY found a good condition used stock 94-95 4.0 manual driveshaft, so I ordered that for cheap. Gonna put new u-joints in it, and steal my new slip yoke from the old stock 87-93 driveshaft. Even if I end up using the TW long term, it won’t be bad at all to have the stock application shaft available to use as a spare.

If this shaft works without leaking, then I’ll know I have a TW problem and can work it out accordingly. I don’t want them wasting effort on it if it’s not their problem and I don’t want to spend my time and money shipping it yet if it’s not bad. So this provides me an easier way to establish a baseline, and I gain a good spare in the process.

So that’s about it for now. It’s so hot out that I’m not really missing any good driving time anyways. I’m just glad some of the pesky things that have bothered me for a while are finally starting to reach their conclusions. I am getting closer and closer to being able to drive it at will and finally stop working on it.

I don’t know when it’ll happen but at some point I want to get some different fog lights. The KCs are cool but they are pretty weak. I might pick up a set of Rigid 360 SAE white/yellow combos. Those are cool and don’t take away from the old school look. Think I’d wire them up to do both colors at once, all the time.

The tire/wheel combination looks great as well.

The tire/wheel combination looks great as well.The tire/wheel combination looks great as well.