Dana 35 4.11 Rebuild

Like I mentioned in

Post #160, I picked up a set of stock 4.10/4.11 axles off of a guy a few hours away that pulled them from a 1995 YJ 2.5L 5-speed. I completed the front axle build and swap back in April 2025, but due to being either busy and/or experiencing poor weather, the rear axle took an additional month to get around to.

Last week, I finally began to teardown the axle, followed by the eventual stripping, cleaning, and reassembling of it for install. Starting last weekend, I drug the axle out to the driveway and put it on jack stands to clean it off.

Documenting its initial condition:

First order of business was to remove the extra curricular. Mostly brake lines and brake line bracket, the rear brake hose, and the breather and breather hose.

Next up was to cut the track bar bracket off, which was mangled and useless by this point. The rear track bar serves very little purpose, so I don't really care about losing it. If the bracket was there, I'd probably run it just because. However, my current tailpipe is in the way of the track bar anyways, and so it wouldn't work in this application regardless. I lopped the bracket off by cutting it close to the base with a 4.5" cutting wheel, then I sanded down the remaining bracketry and welds with an 80-grit flap disc until eventually I was down to the tubes. Overall easy process, just need to exercise a steady hand, caution, and patience.

Once the axle bracket was fully gone, I turned to cleaning. Lots of oven cleaner, Super Clean, scrubbing, and water. After about 2 hours, I finally had it pretty clean and let it dry.

The axle was directly in the sun and dried pretty quickly, at which point I hit it with the needle scaler several times, and then blasted all the rust dust off with the air compressor. Once it was clean and not dusty, I shot it with a couple coats of rust reformer. It started to rain not long after that, plus I had other things to do that day, and so I put the axle back in the garage and left it alone for a few days.

On Monday the following week, I took it back to the driveway for paint. Nothing crazy, just trying to keep it looking black, as opposed to rusty brown. Two coats of VHT epoxy later, and it looked good enough for me.

Finally, this past weekend, I did the rebuild and swap. It took me overall about 2 days, but it involved more than just a straight swapping of axles. I needed the yoke out of the old axle, as well as the axle shafts.

Axle sitting on the pipe stands, ready for me to go to work...

I emptied out the housing by zipping off the pinion nut and hammering the pinion out of the outer bearing. Housing all cleaned off and races removed:

Installed the new pinion races by hammering them into place with the appropriate drivers:

Yanked out the old wheel seals and roller wheel bearings using a slide hammer, and then installed new Spicer flanged double lip seals and Spicer (Koyo) bearings. Interestingly, the original bearings were Torrington brand, which is not what you receive when you buy anything "OEM" today. Words were facing out, so I installed them facing out. Another interesting note is that the stock seals are not flanged, they are just hammered in and I guess you go until they stop. I like the flange style because they put a bead of dry silicone around the outside which works its way up against the axle for extra sealing once the seal is fully installed. Photo below of the finished product, all you can see here is the seal of course.

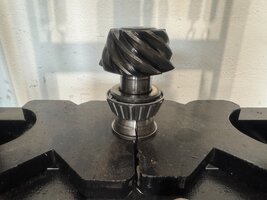

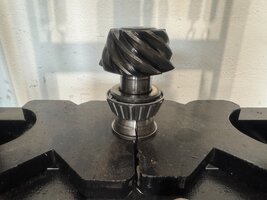

Pinion was ready for its new inner bearing work to be done, so I took it over to a clean workspace so I could work the magic with the clamshell puller.

Ready for pulling using the old race removed from the axle:

Bearing zipped off. I measured the pinion depth shim at 0.038", which is fitting considering this pinion head has a +3 on it, meaning it is a bit deeper than normal. So they used a thinner shim. Most D35's use around a 0.041-0.042" shim on a perfect pinion head.

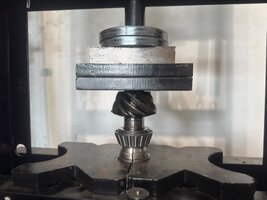

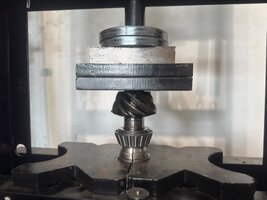

I used a Dremel and cut the old bearing to pieces, saving only the inner race. I took that inner race and cut a slot in it for expansion purposes, so I could use that race to press the new bearing on, without the old race getting stuck on the pinion during the pressing process. Race cut and the pinion, new bearing, and old race assembled in the press:

Came up with a stack of steel stock to waste travel on the press. I wish presses had more intervals for shelf height. I am always having to stack a bunch of crap to reach what I'm pressing.

Pressed on:

No more photos besides the axle under the Jeep, but I continued on by pointing the axle pinion pocket upwards, dropped the outer bearing into its new race, lubricated it and then installed the seal. I dropped a new crush sleeve on the pinion and installed into the axle. Using a new Spicer pinion nut, I zipped it down with an impact until it got tight. Then I kept hitting it with the impact, bit by bit, until the yoke no longer moved in and out (crushing the sleeve to the point where the bearings finally seated in the races - the crush sleeve when uncrushed will keep the bearings completely loose initially).

I made small adjustments from this point using a pipe wrench to hold the yoke, and a breaker bar. This process is not fun. Lots of small adjustments, and then checking to see where you landed. I first landed on 10 inch pounds, then went a tiny bit more and ended up around 19. The spec is 15-35 in-lbs, which honestly, I think 15-20 is what you want. Anymore and it wears the bearings out prematurely. Definitely don't want to do 35 in-lbs if you can avoid it.

Next up was carrier bearings, which I removed the old using the clamshell puller, and then tapped on new bearings using the race of the old bearings. I cut the old rollers and cage off, then just used the race and a race driver. They tap right on in about 5 taps. Dropped the carrier into place and installed the factory outboard shims on the same sides they came from. Oriented bearing caps properly and torqued to 57 ft lbs, per the FSM.

At this point I was ready to throw the axle under the Jeep, so I manhandled it over to the small jack stands I had under the bumper area, and walked it into place and then hooked up the leaf springs. Once it was sitting in place, I reinstalled the drum backing plates, slid in the axle shafts, and bolted one the cover to fill it up with fluid. Of course all the normal stuff too, like hooking up brake lines, bleeding brakes, bolting down the brake line bracket, etc.

Installed:

Not much else to say, it's a pretty simple swap. I will give one pointer though:

Don't turn the axle shafts after inserting into the carrier. I knew this, but didn't think in the moment and one of the spiders fell out. No big deal, except one of the thrust washers rolled 5 feet away and I could not find it. I ended up subbing in an old used thrust washer, which is not ideal. Go figure, once I got everything buttoned up and fluid filled, I then found the thrust washer, and tore it back down to swap the new washer in.

After all the shenanigans were done, I reinstalled the tank on Sunday then went for a drive. It drives well, power/gearing wise. I am happy with 4.11s and 28" tires. Highway speeds are about 2800 rpm at 70, which feels great to me. I'm glad to finally have found a factory set of 4.11 axles that I can use and know they are built right in stock form, and have all new bearings to roll on.