You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

'95 Sahara, 1st YJ

- Thread starter TRevs

- Start date

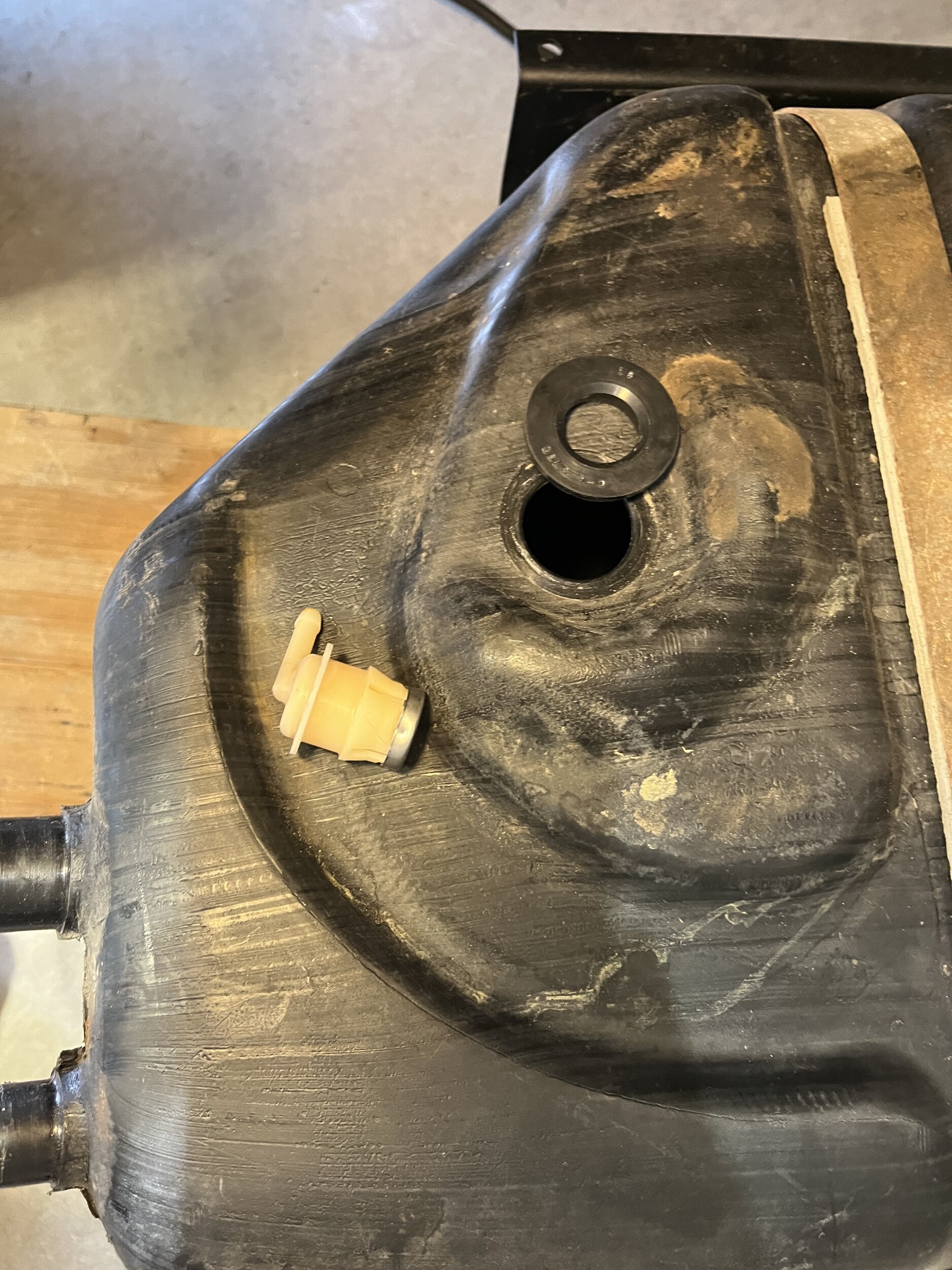

New Crown grommets for the two rollover valves on the gas tank.

I found it easiest to insert the grommet alone first, then push the valve into the grommet. Trial and error.

I found it easiest to insert the grommet alone first, then push the valve into the grommet. Trial and error.

New Crown filler neck and filler vent hoses. The old ones were a pain to get off, and hard to get to because you can’t really drop the tank with hoses on. So I lubed the inside of each hose with plumbers silicone grease which made installation a breeze. Should help next time I drop the tank, too.

The rubber grommet bumper holding the license plate off the tub was worn out; the ACE hardware guy got enthused looking for a suitable replacement. We ended up with a special washer out of the plumbing department. $1.97, and he riveted it to the bracket for free.

The plastic fuel bezel I cleaned up, then sanded with 1500 grit paper, and polished with regular auto polish compound.

The plastic fuel bezel I cleaned up, then sanded with 1500 grit paper, and polished with regular auto polish compound.

Ouch. If you have an Atwoods or Tractor Supply they sell by the lb. Grade 8 being the most expensive, and I can buy a pound of grade 8 hardware for less than that.And new body mounts for that crossmember. The grade 8 bolts were $4.50 each at the local ACE.

View attachment 122119

And here I was thinking i got a good deal. They’re $6-8 each online from Summit or Quadratec. Plus shipping.

Ouch. If you have an Atwoods or Tractor Supply they sell by the lb. Grade 8 being the most expensive, and I can buy a pound of grade 8 hardware for less than that

Carpet turned out great. Did you anchor down the rear lip of the main carpet after it goes up the step, or do you think the wheel well and rear floor portions will hold down enough for the main to not come up or slip out/forward?

I have a can of spray adhesive, but I’m going to wait and see if it needs it. I’ll probably do a bit of minor trimming later anyway.

Right now I’m focusing on figuring out how to extract two rusted-in sheared-off body mount bolts…

Right now I’m focusing on figuring out how to extract two rusted-in sheared-off body mount bolts…

I still haven’t figured out what to do with the two rusted/sheared biday mount bolts. Nine out of 11 isn’t bad right?

To finish the carpet install I needed to create holes in the wheel well cover carpet for the rear seat belt and seat brackets.

I removed the splash shields to access those holes from outside the tub and drilled through to mark the holes.

Then enlarged them with a solder gun to melt them larger.

A tip on getting the splash shield off: there is a middle screw tucked behind the arch of the frame. Since my body mounts are all removed at the moment, I just jacked the tub up to get access to the screw. The extra clearance helped getting the shield in and out.

While the splash shields were off I removed 20 years of dirt and oil and put on a coat of SEM Trim Black.

To finish the carpet install I needed to create holes in the wheel well cover carpet for the rear seat belt and seat brackets.

I removed the splash shields to access those holes from outside the tub and drilled through to mark the holes.

Then enlarged them with a solder gun to melt them larger.

A tip on getting the splash shield off: there is a middle screw tucked behind the arch of the frame. Since my body mounts are all removed at the moment, I just jacked the tub up to get access to the screw. The extra clearance helped getting the shield in and out.

While the splash shields were off I removed 20 years of dirt and oil and put on a coat of SEM Trim Black.

I finally got through the two rusted sheared off body mount bolts. Thankfully the nut plate on the right rear frame rail was salvageable although I did have to cut through the tub to get the remainder of the bolt out.

Its a 1” hole so a standard YJ floor plug fits, and it’s under carpet as well.

Its a 1” hole so a standard YJ floor plug fits, and it’s under carpet as well.

Got in the Jeep on Sunday morning for the weekly Donut Day run, and immediately noticed a very soft clutch pedal. It firmed up about halfway down, and disengaged the gears just above the floor. It was drivable for a short trip, but obviously something was wrong. I suspected clutch hydraulics, but haven’t had to deal with that before. Browsing the forums suggested looking on the interior of the firewall.

Sure enough there’s a seep on the interior side of the master cylinder/piston. I ordered a Dorman replacement from RockAuto ($149 including tax and shipping).

It’s obviously happened before, given the bubbled paint and rust. It was like that when I got it but I didn’t think much of it.

Now to read the FSM while waiting on it to arrive.

I’m starting to think this thread isn’t really a ‘build thread’ as much as it is a ‘repair/replace’ thread.

Sure enough there’s a seep on the interior side of the master cylinder/piston. I ordered a Dorman replacement from RockAuto ($149 including tax and shipping).

It’s obviously happened before, given the bubbled paint and rust. It was like that when I got it but I didn’t think much of it.

Now to read the FSM while waiting on it to arrive.

I’m starting to think this thread isn’t really a ‘build thread’ as much as it is a ‘repair/replace’ thread.

Oddly enough I’ve been through like 5 master/slave cylinder pre-bled assemblies and I’ve never had a single leak that I’ve noticed. It is annoying to never really believe that the clutch hydraulic assembly will ever last a reasonable amount of time. One of the more discouraging aspects of old jeep ownership lol.Got in the Jeep on Sunday morning for the weekly Donut Day run, and immediately noticed a very soft clutch pedal. It firmed up about halfway down, and disengaged the gears just above the floor. It was drivable for a short trip, but obviously something was wrong. I suspected clutch hydraulics, but haven’t had to deal with that before. Browsing the forums suggested looking on the interior of the firewall.

Sure enough there’s a seep on the interior side of the master cylinder/piston. I ordered a Dorman replacement from RockAuto ($149 including tax and shipping).

It’s obviously happened before, given the bubbled paint and rust. It was like that when I got it but I didn’t think much of it.

Now to read the FSM while waiting on it to arrive.

I’m starting to think this thread isn’t really a ‘build thread’ as much as it is a ‘repair/replace’ thread.

View attachment 122332

Just read through your thread this morning. Very nice job! Love that you're going for the lightly modified open air cruiser theme. I went a similar route. I'm rocking 30x9.50s on stock height springs with 1" body mount lift and it looks nice. I'm not going to be doing anything serious, so shouldn't encounter any rub situations.

Thanks for the kind words! I’m considering eventually trying to make it as comfortable as possible to be a 3-4 day per week commuter car. Bulldawg is apparently offering a YJ hard top, and I could add A/C for our super hot summers. Better seats too.Just read through your thread this morning. Very nice job! Love that you're going for the lightly modified open air cruiser theme. I went a similar route. I'm rocking 30x9.50s on stock height springs with 1" body mount lift and it looks nice. I'm not going to be doing anything serious, so shouldn't encounter any rub situations.

Adding the carpet has really helped with road noise reduction, even with no top beyond the bikini.

Carpet definitely is the easy solution for a bit of insulation and sound deadening. I wanted a true 'hose me down' interior, so I opted for durabak. If I have the top down and it comes one of those famous 5 minute 'southern humidity showers', I can throw a plastic bag on the seat and drive.

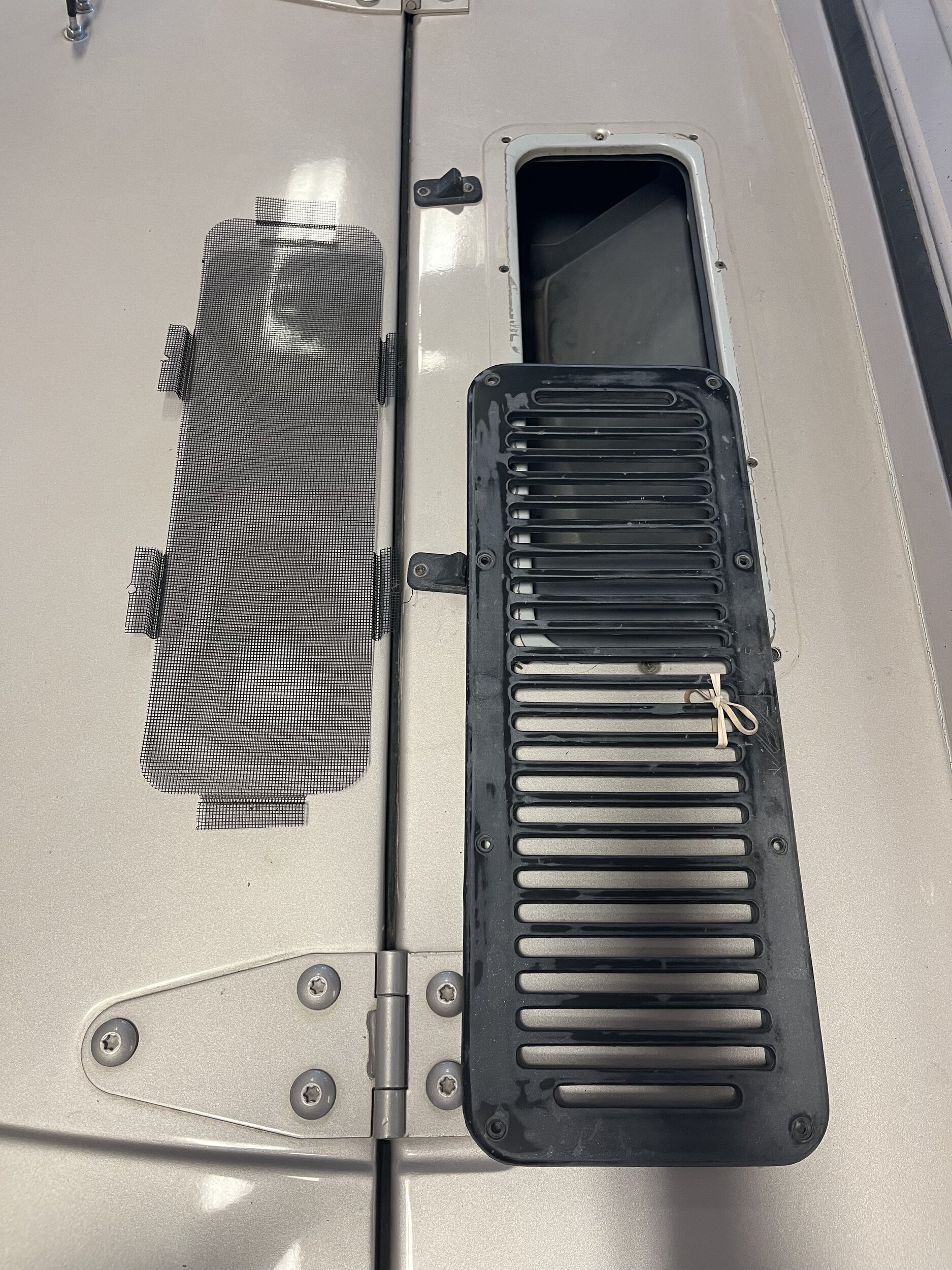

I’ve been refinishing some sad faded trim pieces to give the jeep a newer/restored look. SEM Trim Black gives a nice even durable finish; their rep told me it’s a few shades lighter than true black which can look odd.

Wiper arms, hood cowl vent, OEM mirrors before/after:

Wiper arms, hood cowl vent, OEM mirrors before/after:

Also new interior and exterior door handles (Dorman brand through Rock Auto):

Note the curved hemostat clamp in the photo of new and old exteriot handles; it made it possible to remove and replace the door keepers without removing the window glass as instructed in the FSM.

I gave the inside of the door a good cleaning from 20+ years of dust and leaves, made sure the water drains were clear, repositioned the water dams correctly, and lubed the door latch while everything was apart.

I gave the inside of the door a good cleaning from 20+ years of dust and leaves, made sure the water drains were clear, repositioned the water dams correctly, and lubed the door latch while everything was apart.