Hi all,

New to the YJ forum and I’m looking at getting some advice or a new approach to my problem.

Question is in regard to air in fuel system, I think?

1993 YJ 2.5 manual transmission. Vehicle was mine along time ago and let’s just say it’s in rough shape now as it was parked in a rural environment for over 10 years.

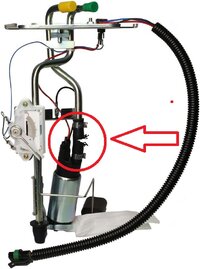

I got it towed to my house and tried to get it running and here are some things I found/did already seeing that I couldn’t get it to run. I admit there was no particular reason or order I did what I did to try to start it nor do I admit the way I did it was the correct way

1. Added enough fresh gas to the tank to try to dilute what very little bit was in the tank from sitting. The tank was practically empty but I knew there was SOME still in it.

2. Tried to start it, nothing.

3. Cut out the access window above the tank to get to the whole fuel unit for a replacement.

4. Replaced the whole gas tank sending unit assembly. The old one fell apart when I pulled it out of the tank, which were my suspicions.

5. Tried again to start it, nothing.

6. Found the wiring diagram for the whole jeep online, started tracing wires and I found an entire bundle of about 10 wires, near the transmission severed in half. Some fed the speedometer sensor, other wires go to the fuel pump. Butt spliced the wires back together

7. Tried to start it and it ran good for about a solid minute and just sputtered to death. Every time after I restarted it, it wouldn’t run for more than 10 seconds probably

8. Looked around online and saw that it could be a clogged filter so I got one from the parts store and replaced it.

When I put the new filter on I noticed how much gas poured out of it and the lines. I just knew air was going to be an issue.

9. Cranked the Jeep for a minute hoping to push the air out back to the tank and it won’t start now.

10. Pressed the needle valve on the Schrader valve and it seemed like a very small amount of air came out but nothing to replace the amount of fuel that came out of the line and filter when I changed the fuel filter

11. I have pressed on the schrader a couple of times and tried cranking the engine and it will fire briefly and then just resume endless cranking.

I also notice when I press on the valve, gas isn’t spraying out like I’d expect. It’s more like a trickle and it will just kind of slowly pour out of the Schrader

12. I tried jumping power to the fuel pump constantly at the relay for roughly 30 seconds and it doesn’t change the spray of gas out of the Schrader valve on the fuel rail.

Does this sound like the new pump assembly is bad already?

Fuel filter is installed in correct direction, but could that be it?

Is this just simply air in the fuel line and if it is, how do I get it out?

(Jumping the pump constantly hot doesn’t seem to help..?)

New to the YJ forum and I’m looking at getting some advice or a new approach to my problem.

Question is in regard to air in fuel system, I think?

1993 YJ 2.5 manual transmission. Vehicle was mine along time ago and let’s just say it’s in rough shape now as it was parked in a rural environment for over 10 years.

I got it towed to my house and tried to get it running and here are some things I found/did already seeing that I couldn’t get it to run. I admit there was no particular reason or order I did what I did to try to start it nor do I admit the way I did it was the correct way

1. Added enough fresh gas to the tank to try to dilute what very little bit was in the tank from sitting. The tank was practically empty but I knew there was SOME still in it.

2. Tried to start it, nothing.

3. Cut out the access window above the tank to get to the whole fuel unit for a replacement.

4. Replaced the whole gas tank sending unit assembly. The old one fell apart when I pulled it out of the tank, which were my suspicions.

5. Tried again to start it, nothing.

6. Found the wiring diagram for the whole jeep online, started tracing wires and I found an entire bundle of about 10 wires, near the transmission severed in half. Some fed the speedometer sensor, other wires go to the fuel pump. Butt spliced the wires back together

7. Tried to start it and it ran good for about a solid minute and just sputtered to death. Every time after I restarted it, it wouldn’t run for more than 10 seconds probably

8. Looked around online and saw that it could be a clogged filter so I got one from the parts store and replaced it.

When I put the new filter on I noticed how much gas poured out of it and the lines. I just knew air was going to be an issue.

9. Cranked the Jeep for a minute hoping to push the air out back to the tank and it won’t start now.

10. Pressed the needle valve on the Schrader valve and it seemed like a very small amount of air came out but nothing to replace the amount of fuel that came out of the line and filter when I changed the fuel filter

11. I have pressed on the schrader a couple of times and tried cranking the engine and it will fire briefly and then just resume endless cranking.

I also notice when I press on the valve, gas isn’t spraying out like I’d expect. It’s more like a trickle and it will just kind of slowly pour out of the Schrader

12. I tried jumping power to the fuel pump constantly at the relay for roughly 30 seconds and it doesn’t change the spray of gas out of the Schrader valve on the fuel rail.

Does this sound like the new pump assembly is bad already?

Fuel filter is installed in correct direction, but could that be it?

Is this just simply air in the fuel line and if it is, how do I get it out?

(Jumping the pump constantly hot doesn’t seem to help..?)