You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hello everyone!

- Thread starter Sorin CNC

- Start date

ACKyj

Member

Barrett-FL

New Member

Nice work!Finally finished the trailer hitches ( one for the rear and one for the fron bumpers). The rear bumper is pretty much done and ready to go to get powder coated ( as well ast the new steps/Bumperettes). I have built in two locations for r the Flag Poles ( 3/4” diameter solid aluminum ) that screw on /off from the bumper. Starting to drill my front bumper for all the accessories so it also can go out for powder coating. The cans/housings for the LED back up/get off my butt lights are also fine and ready to get powder coated. Finally, after all the years that I dreamed to do this, I am finally getting them done..

View attachment 121469

View attachment 121470

View attachment 121471

View attachment 121472

View attachment 121473

View attachment 121474

View attachment 121475

View attachment 121476

View attachment 121477

View attachment 121478

View attachment 121479

View attachment 121480

View attachment 121481

View attachment 121482

Thanks and yes, I will take some pics and post them when I do that. Right now I am working on the new bullet hinges for the hood. I want to try them first before I chop out the hood for the louver insert. Many told me to just bolt the insert over the hood for looks but I am. It doing that.. once done with the hood, I will replace the plastic front bumper cover with a 3/8 aluminum one that I am going to also make my self.Looking good! Love to see pics of the drop down tailgate when you get there. Nice work.

My Custom made Rear bumper steps/Bumperettes are now back from the powder coating. Can’t wait to skim cut all the top surfaces so the frame and the Jeep script shows in aluminum color. The 3 small screws is what I will use to bolt them to the bumper (5/16 stainless steel button head screws. The large hole is used as clearance for the flag poles or canopy poles that will screw into the bumper ( aluminum poles). BTW if you wonder why 3 of them.. Well I always make an extra one in case during the process of making stuff I might screw something up and so I have a spare. In this case they all came out OK so I decided to powder coat it also..

E

E-Rock

Guest

Absolutely. I will need some dimensions for and holes locations. Other than that I can do it and can use your own design. I have a friend that owns Gangster chopper and I can probably can get some of the dimensions from him ( unless you have som old parts and I can use to get my dimensions from)…Looks really Kool!

I was wondering if you've ever made or would consider making a gaurd for an open primary on my Chopper?

View attachment 121652

E

E-Rock

Guest

That would ROCK!

It's an Ultima 6 speed trans, and a RevTech 110 engine. They are STUPID expensive in chrome and I'd be more than happy with something simple and aluminum, just to keep my pant leg intact.

It's an Ultima 6 speed trans, and a RevTech 110 engine. They are STUPID expensive in chrome and I'd be more than happy with something simple and aluminum, just to keep my pant leg intact.

I have one suggestion about the edges of the hinges where you would bevel the edge (no idea if that's the correct term, so correct me if I am wrong, but I have an example). I really like this design though and would be interested in buying one from you if you would be willing to produce another.So I didn’t feel like messing around in the shop and started to play designing parts. I decided that the cheesy hood hinges needed to go. So here is what I came up with. Theh hinges will be made out of aluminum billet and then powder coated flat black. Top and sides of the text will be re machined after that. The flat surfaces thickness will be 3/8” and the round diameter of the hinges will be 3/4”. 3/8 stainless steel pivoting pin. Please tell me what you think??

View attachment 121486

All edges will have to be beveled/chamfered. Sharp corners are ugly, dangerous and get banged up quickly. Let me work on these hinges and have a working prototype first. Once I do that and make the first set I will gladly make you a set. Thanks for watching my progress on these parts. Finishing the Front bumper “Medalion” today!I have one suggestion about the edges of the hinges where you would bevel the edge (no idea if that's the correct term, so correct me if I am wrong, but I have an example). I really like this design though and would be interested in buying one from you if you would be willing to produce another.

View attachment 121657

My rear bumper steps/ Bumperettes are done at the powder coating shop and can’t wait to get them and recut the high spot surfaces to expose the aluminum color. They will mount on top of the rear bumper and also provide holes for the aluminum flag poles that I am making for the back bumpers ( removable of course).

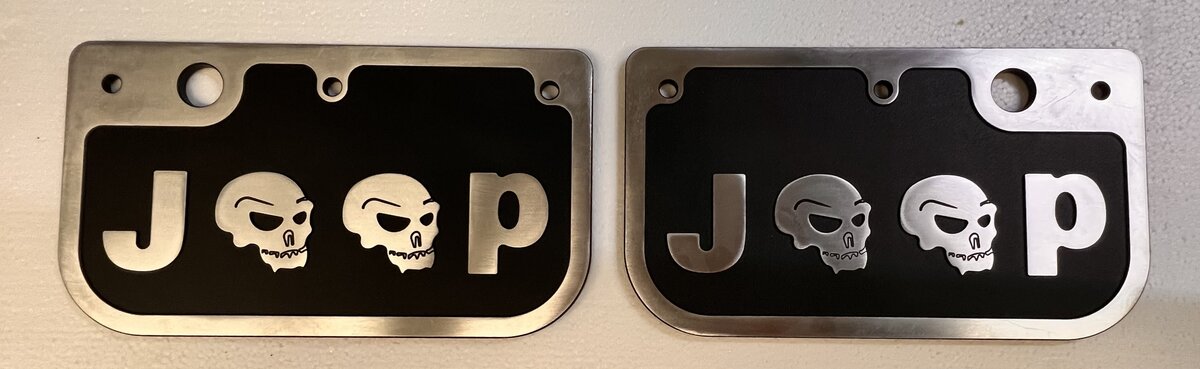

Here is the front bumper Jeep Medalion. Made of 5/8 thick aluminum plate. All that I need to do is sand blast it to remove tool shine marks and powder coat it. The high spots will be remachined after powder coating to expose the aluminum color.. The bumpers are made out 2”X6” steel tubing that is 1/4” thick. Not bending them bumpers..

Attachments

Looks really Kool!

I was wondering if you've ever made or would consider making a gaurd for an open primary on my Chopper?

View attachment 121652

I could do it. I will need some type of dimensional sketch for the basic shape, holes and hole locations. After hat, the possibilities wold be unlimited mites..

My Custom made Rear bumper steps/Bumperettes are now back from the powder coating. Can’t wait to skim cut all the top surfaces so the frame and the Jeep script shows in aluminum color. The 3 small screws is what I will use to bolt them to the bumper (5/16 stainless steel button head screws. The large hole is used as clearance for the flag poles or canopy poles that will screw into the bumper ( aluminum poles). BTW if you wonder why 3 of them.. Well I always make an extra one in case during the process of making stuff I might screw something up and so I have a spare. In this case they all came out OK so I decided to powder coat it also..

View attachment 121651

Just finished my rear bumper steps. The bumpers, trailer hitches, LED lights cans and covers are still at the powder coating shop. I have been sick for the past 3 weeks and I am scheduled to be admitted in the hospital this Sunday evening.

Sorry to hear of your problems and good luck.Just finished my rear bumper steps. The bumpers, trailer hitches, LED lights cans and covers are still at the powder coating shop. I have been sick for the past 3 weeks and I am scheduled to be admitted in the hospital this Sunday evening.

View attachment 121730