New here and enjoying it very much. I own a 1994 YJ . It has only 78,000 original miles. I used to own a CNC machine shop prior to my retirement ( 68 years old) and I kept few machines just so I can make stuff for my Georgie ( named it after my late Father) and my wife’s C6 Corvette. I am currently in process of doing all custom work for it and I will try to post some pics as the project moves along. BTW, one of my twin daughters has a 97 YJ and I did lots of stuff for her also. So here is my Georgie!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Hello everyone!

- Thread starter Sorin CNC

- Start date

My new wheel center hub covers and foot rests. All Aluminum Billet.

The new Aluminum Billet side view mirrors ( they are out to be powder coated as well as the replacement for the Bumperettes ( they also need to get powder coated. I have been waiting for years to finally have the time to make all that stuff for my Jeep.

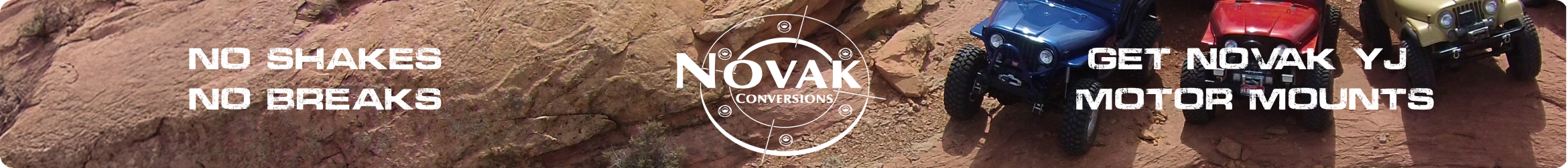

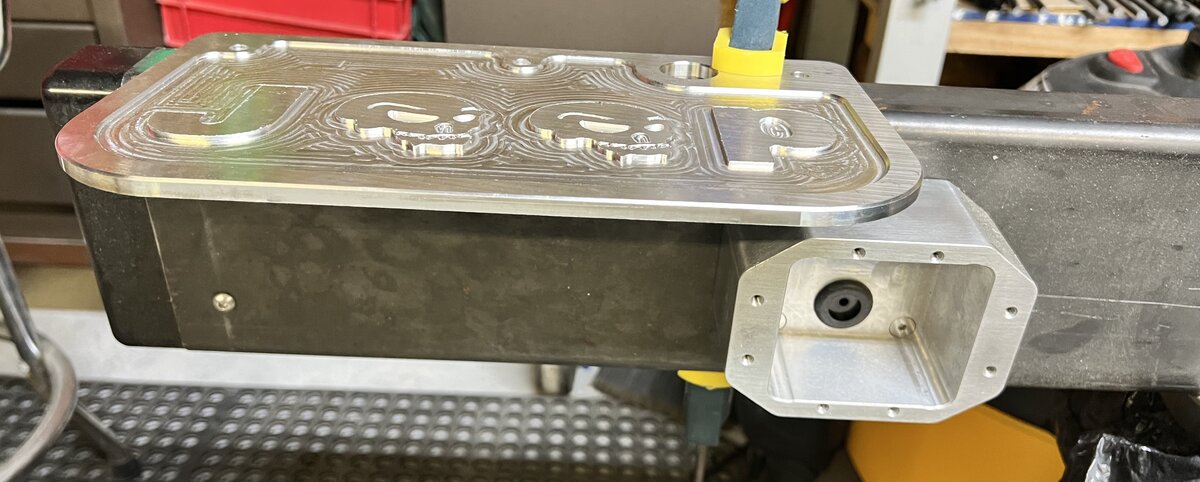

Finally finished the trailer hitches ( one for the rear and one for the fron bumpers). The rear bumper is pretty much done and ready to go to get powder coated ( as well ast the new steps/Bumperettes). I have built in two locations for r the Flag Poles ( 3/4” diameter solid aluminum ) that screw on /off from the bumper. Starting to drill my front bumper for all the accessories so it also can go out for powder coating. The cans/housings for the LED back up/get off my butt lights are also fine and ready to get powder coated. Finally, after all the years that I dreamed to do this, I am finally getting them done..

Thank you! The bumper steps are getting to be powder coated flat black like the bumper and the trailer hitch. Once they are done, I will skim cut the top of them slightly and all the high surfaces will be back to the original aluminum color.. I started to work in he spindle for the swing open spare tire carrier. I am going to use wheel bearings for tol and bottom for a nice , smooth and no play movement. I just need to figure where and how to attach it to the bumper. I don’t want to weld it to the bumper because I want to be able to remote it easily since I am not a big fan of driving around with the spare on the back of the Jeep. I have other plans for that spot… LOLIt all looks great, and those are some real purdy welds.

Sounds like a fine job, and the steps will look great.Thank you! The bumper steps are getting to be powder coated flat black like the bumper and the trailer hitch. Once they are done, I will skim cut the top of them slightly and all the high surfaces will be back to the original aluminum color.. I started to work in he spindle for the swing open spare tire carrier. I am going to use wheel bearings for tol and bottom for a nice , smooth and no play movement. I just need to figure where and how to attach it to the bumper. I don’t want to weld it to the bumper because I want to be able to remote it easily since I am not a big fan of driving around with the spare on the back of the Jeep. I have other plans for that spot… LOL

Thank you!Sounds like a fine job, and the steps will look great.

I am game for anything. I used to teach CadCam software as a contractor for 16.5 years. I scaled down my shop bc and now I have a 1,800 square foot shop on my property. Air conditioned and as far as milling is concerned, I can do up to 4axis on my Haas Mill. I also do turning work.Your CNC skills are impressive!

Would you have any interest in taking on a project or two I have in mind for my KUSTOM project?

I've had several components printed by a 3D fella in IN, but some of my ideas will require more strength than plastic can offer.

No pictures today.. Designing and making brackets for the front bumper. Also designed and programmed new set of shackles. .375 stainless material so I wouldn’t worry about them

Getting rusty.. . Once done with the bumpers, while waiting for the powder coating to be done, I will remove the hood and cut the openings for air intake.. I am

Installing a working louver insert.. Also making some real billet hinges for the hood..

Getting rusty.. . Once done with the bumpers, while waiting for the powder coating to be done, I will remove the hood and cut the openings for air intake.. I am

Installing a working louver insert.. Also making some real billet hinges for the hood..

E

E-Rock

Guest

That's awesome! As I progress along with the mock up this summer I suspect I'll have a few projects for you to work on. I'll keep your info handy!

No problem. I am

Extremely busy right now anyways. Besides the hood, I am

Making hinges to have a drop down tailgate for the YJ. Making all the hinge using sealed ball bearings.. modifying the roll cage so I can build a polycarbonates, UV and scratch resistant top for the Jeep. Back polycarbonate back window behind front seats with Jeep Ligo and built in LED lights.. I have about 15 years worth of dreams that I want to get done by the end of the year.. LOL

Extremely busy right now anyways. Besides the hood, I am

Making hinges to have a drop down tailgate for the YJ. Making all the hinge using sealed ball bearings.. modifying the roll cage so I can build a polycarbonates, UV and scratch resistant top for the Jeep. Back polycarbonate back window behind front seats with Jeep Ligo and built in LED lights.. I have about 15 years worth of dreams that I want to get done by the end of the year.. LOL

Finally finished the trailer hitches ( one for the rear and one for the fron bumpers). The rear bumper is pretty much done and ready to go to get powder coated ( as well ast the new steps/Bumperettes). I have built in two locations for r the Flag Poles ( 3/4” diameter solid aluminum ) that screw on /off from the bumper. Starting to drill my front bumper for all the accessories so it also can go out for powder coating. The cans/housings for the LED back up/get off my butt lights are also fine and ready to get powder coated. Finally, after all the years that I dreamed to do this, I am finally getting them done..

View attachment 121469

View attachment 121470

View attachment 121471

View attachment 121472

View attachment 121473

View attachment 121474

View attachment 121475

View attachment 121476

View attachment 121477

View attachment 121478

View attachment 121479

View attachment 121480

View attachment 121481

View attachment 121482

Well, I finished my Front bumper brackets today and got them all setup and holding the bumper level vertically and horizontally.. then I just got my first design for the shackles. I have something else in mind but that will be tomorrow. Had a bad Diabetes Day today.. please let me know what you think. Material will be stainless steel powder coated black then re finish the top to expose the plain stricken color. BTW, they will be 3/8 thick.

E

E-Rock

Guest

Now THERE'S something I can relate to! I've spent the last 20+ configuring modifications. I never really believed half of my ideas would come to fruition, yet here I am. About 6 months and 2 gallons of paint away!No problem. I am

Extremely busy right now anyways. Besides the hood, I am

Making hinges to have a drop down tailgate for the YJ. Making all the hinge using sealed ball bearings.. modifying the roll cage so I can build a polycarbonates, UV and scratch resistant top for the Jeep. Back polycarbonate back window behind front seats with Jeep Ligo and built in LED lights.. I have about 15 years worth of dreams that I want to get done by the end of the year.. LOL

You got to continue chasing your dreams. My problem was that I had the ideas, had the know how, had equipment to do it.. The only thing that I didn’t have was time. “Retired 6 years ago ( at 62) and worked more than I ever did since. Loving every minute of it and not planning to slow down. BTW, I am also an insulin dependent Diabetic on the pump. Hope that I serve as an example to the younger guys out there.Now THERE'S something I can relate to! I've spent the last 20+ configuring modifications. I never really believed half of my ideas would come to fruition, yet here I am. About 6 months and 2 gallons of paint away!

E

E-Rock

Guest

Three years ago, at 50, I had a MAJOR, irreverserable, medical procedure that has been life altering. I've recovered, as much as feasible. But will never be the same. I've NOT allowed this to alter my dream!

I traveled the PCH, Jan of 2005. The crummy rental car I was in, was no way capable of traversing the many mountain trails, and beach passes that dart off from left to right. I made it my ambition to rebuild my Jeep, and get er' out there!

I've about two yrs left of a Naval/Postal career. I plan on touring the country with my "NEW" YJ and Kustom Bantam camper once I'm finished. Who knows... I could end up in a town near you!

I traveled the PCH, Jan of 2005. The crummy rental car I was in, was no way capable of traversing the many mountain trails, and beach passes that dart off from left to right. I made it my ambition to rebuild my Jeep, and get er' out there!

I've about two yrs left of a Naval/Postal career. I plan on touring the country with my "NEW" YJ and Kustom Bantam camper once I'm finished. Who knows... I could end up in a town near you!

I love it! Never give up. We are our own limitations. Two years ago I got sick with Covid ( and because my age and being. Full blown Diabetic) I only had 10% chance to survive. I was in the hospital for 6 weeks and fit the first two. I had no clue where and who I was.. Still have issues from that but I am moving on.. and no, I still never got vaccinated. I just had a wonderful doctor..Three years ago, at 50, I had a MAJOR, irreverserable, medical procedure that has been life altering. I've recovered, as much as feasible. But will never be the same. I've NOT allowed this to alter my dream!

I traveled the PCH, Jan of 2005. The crummy rental car I was in, was no way capable of traversing the many mountain trails, and beach passes that dart off from left to right. I made it my ambition to rebuild my Jeep, and get er' out there!

I've about two yrs left of a Naval/Postal career. I plan on touring the country with my "NEW" YJ and Kustom Bantam camper once I'm finished. Who knows... I could end up in a town near you!

So I didn’t feel like messing around in the shop and started to play designing parts. I decided that the cheesy hood hinges needed to go. So here is what I came up with. Theh hinges will be made out of aluminum billet and then powder coated flat black. Top and sides of the text will be re machined after that. The flat surfaces thickness will be 3/8” and the round diameter of the hinges will be 3/4”. 3/8 stainless steel pivoting pin. Please tell me what you think??

I just got my side mirrors back from the powder coating. I love the way they came out. Bumpers will be going out for powder coat Monday Morning.Finally finished the trailer hitches ( one for the rear and one for the fron bumpers). The rear bumper is pretty much done and ready to go to get powder coated ( as well ast the new steps/Bumperettes). I have built in two locations for r the Flag Poles ( 3/4” diameter solid aluminum ) that screw on /off from the bumper. Starting to drill my front bumper for all the accessories so it also can go out for powder coating. The cans/housings for the LED back up/get off my butt lights are also fine and ready to get powder coated. Finally, after all the years that I dreamed to do this, I am finally getting them done..

View attachment 121469

View attachment 121470

View attachment 121471

View attachment 121472

View attachment 121473

View attachment 121474

View attachment 121475

View attachment 121476

View attachment 121477

View attachment 121478

View attachment 121479

View attachment 121480

View attachment 121481

View attachment 121482