The Diesel Jeep Build:

A bit wordy but designed to make it a fun read with a background as to reasons why on the build.

First off I will apologize in advance as this isn't really a YJ Wrangler but a CJ-7 that I am working on.

Now that I have that out of the way, the reason I have placed it here is because much and many of the diesel Jeep conversions out there involve YJ Wranglers which are a very close cousins of the CJ-7. So much of the build will have direct relevance to anyone looking to do such a conversion on their YJ 1st or 1 1/2 generation Jeep Wrangler. Having owned 3 YJ Wranglers over the years, I can say that they are more "alike" than different to the CJ line of Jeeps perhaps than even to a TJ Wrangler predecessor that came after.

Suspensions are almost identical, axles are similar, layout is nearly the same and believe it or not, all Jeep Wranglers from 1987 until the end of the 2nd gen TJ are dimensionally almost the same, (within 1/2" in all major body layout dimensions). In fact the YJ Wrangler tub will nearly bolt onto a CJ-7 frame and a CJ-7 front hood, fenders, grill and dashboard will literally "bolt right up" to a YJ Wrangler requiring no real modifications whatsoever.

So with these explanations out of the way, I will begin to rough out over the course of the next several months "The Diesel Jeep Build" and will welcome all Jeep owners of any year breed to freely comment and even encourage posting of images if you yourself have taken the leap to "Oil Burner" status. Consider this to be the home on all of @Chris sites for any Jeep that does not contain Spark plugs yet does not run strictly off of electrons and magnetism. If you have a diesel hybrid, you may post here also.

Another point I will make is that if you own a factory diesel Jeep of any kind, feel free to post it here as well, I will not consider it hijacking to discuss diesel motive Jeeps of any kind but I will be posting pictures of my build as it goes and may introduce pictures of a previous engines not diesel that were in this build I've swapped before in prior lives mentioned.

Background:

I've done lots of motor swaps in a few Jeeps over the years and two decades back when I owned a black 1995 YJ S model Wrangler while wheeling the famed Rubicon Trail I met up with a guy who had a similarly equipped FJ sporting a diesel engine coming down Cadillac Hill while I was going up. The very tired 2.5L AMC 4-cylinder 3-speed automatic was very noisy and had extremely low oil pressure. I had repaired it after a failure from the previous owner who never changed the oil, merely "added" more oil...... All the time! And as we know, more is always better right? WRONG! The motor was loud and rattled like a diesel so the FJ owner stopped me on the trail to "compare" notes.

Thus germinated the seed that was planted in my mind of someday owning "The Diesel Jeep Build" and the rest, history........

Having owned 12 different Jeeps over the last quarter century give-or-take, that germinated seed grew and grew until I finally pulled the trigger on the build we come to now. That guy's above mentioned FJ had an old Detroit 6.2L GM V8 in it and an NV4500 GM variant 5-speed 1-ton transmission with the rest still being the Toyota frame, transfer case & axles. What intrigued me was he claimed to be getting North of 25MPG fuel economy and could drive "round trip" from the SF bay area to the Rubicon Trail, play for a week then drive back on ONE 26 Gallon Tankful! I was hooked!

Certainly, I am now a Jeep guy but before I drove Jeeps, I drove Suzuki's and knew the elusive good fuel economy that could be obtained in a 4x4 vehicle because my Suzuki 4x4 routinely would get better than 24MPG HWY even geared down with relatively big tires, although WAY under powered as it was. I was searching for that same kind of economy when I finally moved "up to a Jeep" which I had always wanted but couldn't afford as a poor younger driver. The shock though was from Jeep getting relatively poor economy with the 4 or 6 cylinder engine of roughly 12-14MPG BEST. This meant a round trip to the Rubicon Trail would take a minimum of 3 to 4 tanks full in either of my Wranglers at the time and carrying extra Jerry cans to have any long range. YUCK!

Moving forward:

By the time two plus decades rolled around, I had owned nearly a dozen Jeeps and none of them got what I would call spectacular MPG. Some were definitely better than others 18.5 in my 5-speed 2dr 4x4 4.0L XJ, and some stock ones or properly geared ones got fairly good mileage compared to friends who also had 4x4's of comparable capability. I had a CJ a long long time ago (not saying how long) but long enough that a new one was under $10K out the door! Let's leave it at that as I don't like being called a geezer, senior or old dude quite yet. I don't feel I'm getting grey and old and you are only as old as you feel RIGHT GUYS???? All my kids are under 10 so I must still be young.... Yeah right, who said don't have kids 'till you can afford them? That would be like just before you're ready to RETIRE! Nevermind, I love my kids and wouldn't change a thing!

I happened to be one day, as someone else I know from another forum said: "Smoking the Jeepers Crack" (called Craigslist) and found a VERY cheap old Jeep. I didn't know exactly how old because the add didn't give specifics but it said old Jeep for sale $1500 OBO and had a photo of a half-engulfed in a giant Bougainvillea, Jeep front end sticking out of it. Not pretty but at this time (20 years ago) CJ's and YJ's were commanding relatively big money on the used market and from what I could see, it looked straight and rust free. Before I drove about an hour away to "see" what the seller had for sale I called to talk to him. He told me it was at a friends house in the back yard and they were selling the house so it had to go TODAY! It was a Saturday morning and I could go look, he said he wasn't available and that others wanted it but I insisted to let me drive over and check it out first then wait for him to show later that afternoon. He reluctantly agreed and said OK. I took down the address and drove straight out there after swinging by a friends house and "borrowing" a few hundred in cash (I did a lot for this guy on his YJ so you could call it owing a favor so to speak). Cash is king and I wanted close to his asking price so I could wave some around and see if he'd bite on it. That is, if I decided I wanted it after actually seeing it. Long story short, the motor was in a crate in the back of the Jeep. Parts were in a nearby shed and it didn't have any registration for over 7-years. He was a Jeep mechanic and bought it from a customer who blew the motor on it and traded it in for another newer Jeep. Word was something like he bought it from the dealership for the guy's down payment on SAID NEW JEEP and planned (for the last 7-years) to put a new warranty motor he had at work in it. The AMC 2.5L 4-cylinder out of a 2002 TJ, (just coming out new at the time) Wrangler with fuel injection and all that goes with the conversion. He never got around to it and had to stash everything in a friends back yard until several years later the friend wanted to sell his house and clean up the back yard "mess" first. That's where I came into the picture.

Turns out it was a CJ-7 and was 100% complete except for the original hard top and full doors were robbed off it by another friend of the PO's for his Jeep so it had YJ half doors and a bikini top instead. The seller knew his buddy wanted to swap the top but had no idea he actually did swap the parts already. This virtually destroyed the carpet and interior of the Jeep, (great negotiating point though), that and the Bougainvillea plant growing throughout the cab and rest of it. Only the hood and one fender were visible from the overgrown thorn bearing monster plant! I asked the home owner if I could "hack the bush back to get at the Jeep" and he said FINE DO IT, I want it all GONE! He even lent me the pruning sheers and a pole chain saw to cut it away with. 15 minutes later, there was a nice relatively unmolested original paint white CJ-7 with everything to put the motor back together in the back cargo area. I negotiated $1200 fast cash and called AAA for a flatbed home! DONE!

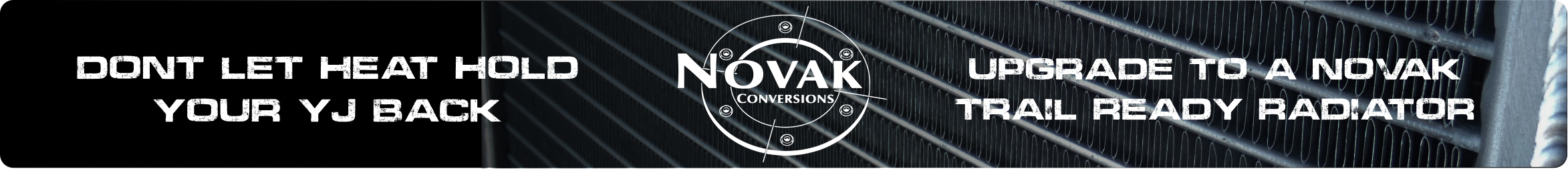

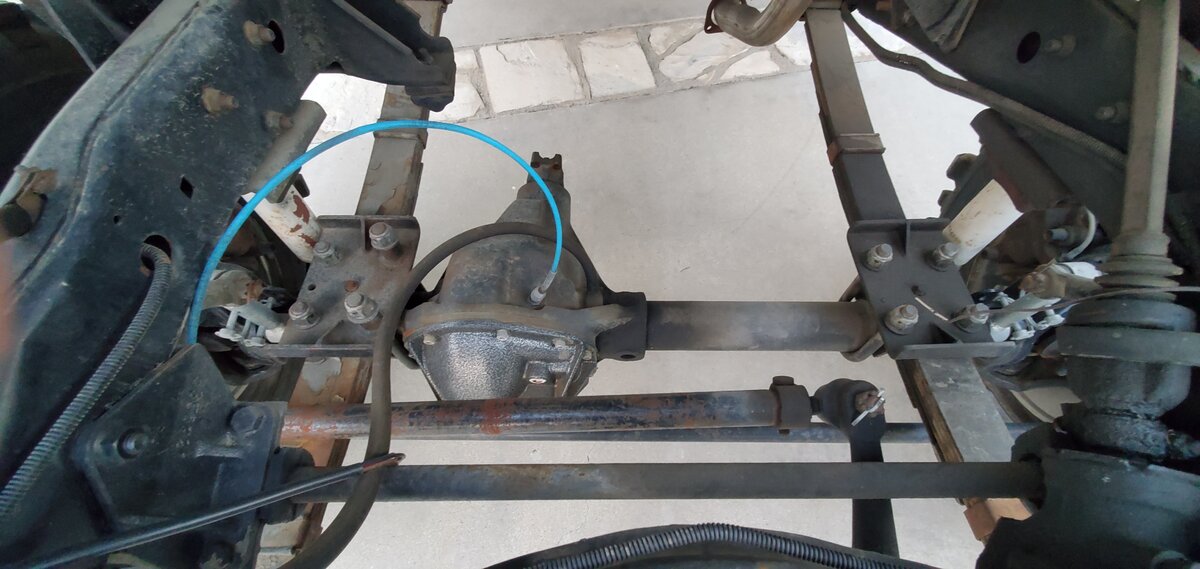

Over the years I made slow improvements to the CJ-7 such as replacing both factory axles with built premium axles. I cleaned the interior and installed a nice stereo, CB & ham radio. There was also a Tuffy locking console installed and new off-road lights. The Jeep had a Rancho 2 1/2" lift kit installed probably pretty close to when it was new by the shape of all the bushings and shocks. I removed that lift and installed a hybrid SOA/SUA at the time I upgraded both axles. I figured when I am ready to install the diesel engine, I wanted everything else in the Jeep to be up to the task. I rebuilt the factory tilt GM steering column, the clutch petals and booster. I also converted the Jeep to 4-wheel disc brakes when I swapped the rear axle. The front end got crossover high steering, a new thicker one-piece welded power steering bracket and heavy duty AGR rock-box. 1-ton steering by Rough-Stuff and new heavy duty lockout hubs by Mile Marker. I still had an old Super Top BesTop frame in the garage for my last trail riding YJ so I swapped that on it and bought a brand new skin with windows for it. Luckily I also had the YJ half upper wire frames so new skins for them and the doors were ready to go.

What's nice about the YJ wrangler and the CJ-7 body is dimensionally they are so similar, most of the parts interchange so I was able to use the YJ Wrangler SuperTop and factory metal YJ half doors on the CJ. Also the uppers fit great too. Even the back seat fits with minor adjustment from YJ to CJ-7!

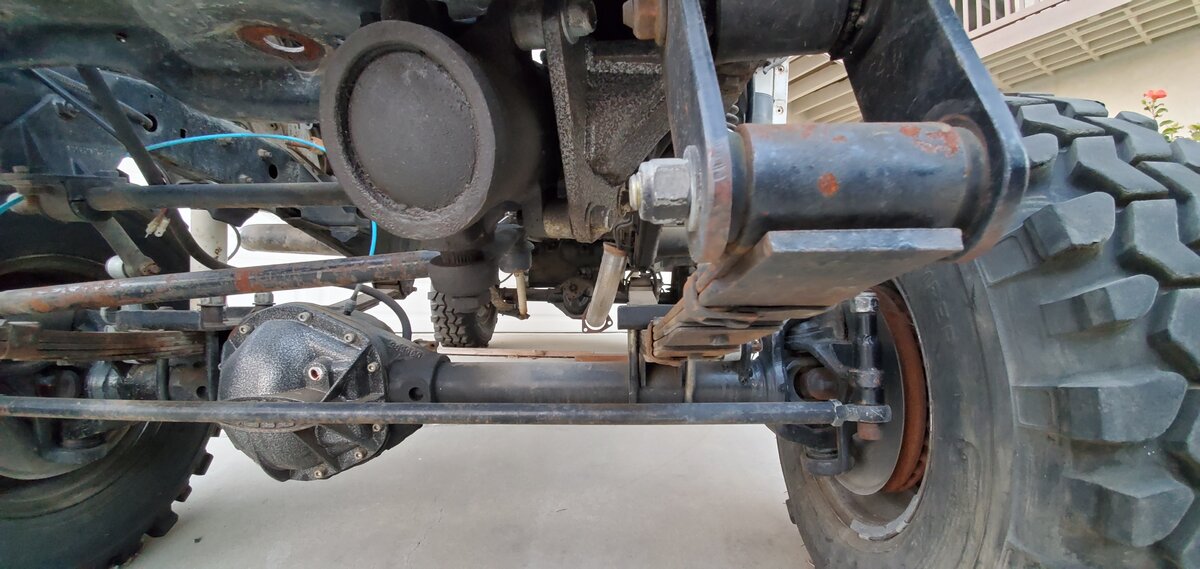

When I did the axle swaps I also reached into my old YJ pile-O-parts that were saved and installed Pro-Comp YJ Wrangler 4" lift kit in the rear straight off the YJ and onto the CJ. They are an exact fit and still SUA out back. The shocks also fit with some mods to the mounting tabs on the new rear Ford 8.8 axle I used. Up front I used a fresh pair of stock 6-cylinder hard top heavy YJ 2.5" wide leaf springs in SOA configuration over the new GM Camper Spl Dana 44 front axle I built for the CJ. The front shocks were ordered specific for application because the YJ uses studs on top instead of eyes on both ends like the CJ does. Both axles have 4.10 gears and lockers. Front is an ARB, back has a full case Detroit and then armored covers.

I also reached again into the stack of YJ spare parts-O-plenty for the front and rear 4" lift extended SS brake lines from the YJ ProComp lift kit. They fit perfectly!

Here is where we come to The Diesel Jeep Build part and I will post photos over the next several weeks along with some photos I have from various other upgrades like the axles since all this tech is VERY similar to YJ Wranglers, just a little different.

The Jeep was originally a 4-cylinder AMC 2.5L powered T-4 4 Speed Jeep. I unbolted the motor mounts and bought M.O.R.E. V8 motor mounts for a short-lived Chevy 350 V8 TBI engine swap I had going. That came out and gave way for a 5.3L Vortec V8 Gen III gasser that was in there with another set of M.O.R.E. mounts. That engine and transmission were sold to another forum member for his TJ Wrangler and the engine bay is now EMPTY and ready for the Cummins BT engine I have in a crate. It is an ex-Frito-Lay bread/chips delivery van "Cummins Re-Power Program" fleet engine. It went almost 300K with another engine, then was removed and factory Cummins Remanufactured engine refit program motor installed. It has around 45K since the refit before retiring the van and runs great.

This Cummins motor was originally setup for a GM Allison 1000 2WD automatic but the seller was kind enough to swap the SAE to bellhousing adapter out for a Ford style and flywheel so I could use my ZF s5-42 5-speed O.D. manual. I am going to have to flip the oil pan to rear sump because it is currently front sump so I need another pickup tube.

Now I am working on the sump and cleaning up the engine to get it ready. I am also working on the engine bay and mocking up the engine mounts.

Design criteria for the mounts:

1. Support and position the powertrain with enough strength to keep the mounts from getting damaged in severe rock crawling torque use.

2. Clearance for the body and hood maintained along with positioning for drive shaft clearance.

3. Help to isolate vibrations from the powertrain while running, (recommended Cummins engineering is above the centerline of the crankshaft) to accomplish this.

4. Transmission/transfer case mount with similar criteria.

Looking into fluid filled mounts from some other widely used application to reduce cost and increase ease of sourcing the mount.

Pictures to follow of where we are at soon.... I will edit this to add more and any table of contents as time goes by with posts.

Rebuilding the D300 transfer case with a JB conversions 4:1 and 32 spline HD output shaft. This will also get a conversion input spud shaft kit for mating to the ZF s5-42 transmission at the same time.

Thanks for looking,

more to follow......

RR

A bit wordy but designed to make it a fun read with a background as to reasons why on the build.

First off I will apologize in advance as this isn't really a YJ Wrangler but a CJ-7 that I am working on.

Now that I have that out of the way, the reason I have placed it here is because much and many of the diesel Jeep conversions out there involve YJ Wranglers which are a very close cousins of the CJ-7. So much of the build will have direct relevance to anyone looking to do such a conversion on their YJ 1st or 1 1/2 generation Jeep Wrangler. Having owned 3 YJ Wranglers over the years, I can say that they are more "alike" than different to the CJ line of Jeeps perhaps than even to a TJ Wrangler predecessor that came after.

Suspensions are almost identical, axles are similar, layout is nearly the same and believe it or not, all Jeep Wranglers from 1987 until the end of the 2nd gen TJ are dimensionally almost the same, (within 1/2" in all major body layout dimensions). In fact the YJ Wrangler tub will nearly bolt onto a CJ-7 frame and a CJ-7 front hood, fenders, grill and dashboard will literally "bolt right up" to a YJ Wrangler requiring no real modifications whatsoever.

So with these explanations out of the way, I will begin to rough out over the course of the next several months "The Diesel Jeep Build" and will welcome all Jeep owners of any year breed to freely comment and even encourage posting of images if you yourself have taken the leap to "Oil Burner" status. Consider this to be the home on all of @Chris sites for any Jeep that does not contain Spark plugs yet does not run strictly off of electrons and magnetism. If you have a diesel hybrid, you may post here also.

Another point I will make is that if you own a factory diesel Jeep of any kind, feel free to post it here as well, I will not consider it hijacking to discuss diesel motive Jeeps of any kind but I will be posting pictures of my build as it goes and may introduce pictures of a previous engines not diesel that were in this build I've swapped before in prior lives mentioned.

Background:

I've done lots of motor swaps in a few Jeeps over the years and two decades back when I owned a black 1995 YJ S model Wrangler while wheeling the famed Rubicon Trail I met up with a guy who had a similarly equipped FJ sporting a diesel engine coming down Cadillac Hill while I was going up. The very tired 2.5L AMC 4-cylinder 3-speed automatic was very noisy and had extremely low oil pressure. I had repaired it after a failure from the previous owner who never changed the oil, merely "added" more oil...... All the time! And as we know, more is always better right? WRONG! The motor was loud and rattled like a diesel so the FJ owner stopped me on the trail to "compare" notes.

Thus germinated the seed that was planted in my mind of someday owning "The Diesel Jeep Build" and the rest, history........

Having owned 12 different Jeeps over the last quarter century give-or-take, that germinated seed grew and grew until I finally pulled the trigger on the build we come to now. That guy's above mentioned FJ had an old Detroit 6.2L GM V8 in it and an NV4500 GM variant 5-speed 1-ton transmission with the rest still being the Toyota frame, transfer case & axles. What intrigued me was he claimed to be getting North of 25MPG fuel economy and could drive "round trip" from the SF bay area to the Rubicon Trail, play for a week then drive back on ONE 26 Gallon Tankful! I was hooked!

Certainly, I am now a Jeep guy but before I drove Jeeps, I drove Suzuki's and knew the elusive good fuel economy that could be obtained in a 4x4 vehicle because my Suzuki 4x4 routinely would get better than 24MPG HWY even geared down with relatively big tires, although WAY under powered as it was. I was searching for that same kind of economy when I finally moved "up to a Jeep" which I had always wanted but couldn't afford as a poor younger driver. The shock though was from Jeep getting relatively poor economy with the 4 or 6 cylinder engine of roughly 12-14MPG BEST. This meant a round trip to the Rubicon Trail would take a minimum of 3 to 4 tanks full in either of my Wranglers at the time and carrying extra Jerry cans to have any long range. YUCK!

Moving forward:

By the time two plus decades rolled around, I had owned nearly a dozen Jeeps and none of them got what I would call spectacular MPG. Some were definitely better than others 18.5 in my 5-speed 2dr 4x4 4.0L XJ, and some stock ones or properly geared ones got fairly good mileage compared to friends who also had 4x4's of comparable capability. I had a CJ a long long time ago (not saying how long) but long enough that a new one was under $10K out the door! Let's leave it at that as I don't like being called a geezer, senior or old dude quite yet. I don't feel I'm getting grey and old and you are only as old as you feel RIGHT GUYS???? All my kids are under 10 so I must still be young.... Yeah right, who said don't have kids 'till you can afford them? That would be like just before you're ready to RETIRE! Nevermind, I love my kids and wouldn't change a thing!

I happened to be one day, as someone else I know from another forum said: "Smoking the Jeepers Crack" (called Craigslist) and found a VERY cheap old Jeep. I didn't know exactly how old because the add didn't give specifics but it said old Jeep for sale $1500 OBO and had a photo of a half-engulfed in a giant Bougainvillea, Jeep front end sticking out of it. Not pretty but at this time (20 years ago) CJ's and YJ's were commanding relatively big money on the used market and from what I could see, it looked straight and rust free. Before I drove about an hour away to "see" what the seller had for sale I called to talk to him. He told me it was at a friends house in the back yard and they were selling the house so it had to go TODAY! It was a Saturday morning and I could go look, he said he wasn't available and that others wanted it but I insisted to let me drive over and check it out first then wait for him to show later that afternoon. He reluctantly agreed and said OK. I took down the address and drove straight out there after swinging by a friends house and "borrowing" a few hundred in cash (I did a lot for this guy on his YJ so you could call it owing a favor so to speak). Cash is king and I wanted close to his asking price so I could wave some around and see if he'd bite on it. That is, if I decided I wanted it after actually seeing it. Long story short, the motor was in a crate in the back of the Jeep. Parts were in a nearby shed and it didn't have any registration for over 7-years. He was a Jeep mechanic and bought it from a customer who blew the motor on it and traded it in for another newer Jeep. Word was something like he bought it from the dealership for the guy's down payment on SAID NEW JEEP and planned (for the last 7-years) to put a new warranty motor he had at work in it. The AMC 2.5L 4-cylinder out of a 2002 TJ, (just coming out new at the time) Wrangler with fuel injection and all that goes with the conversion. He never got around to it and had to stash everything in a friends back yard until several years later the friend wanted to sell his house and clean up the back yard "mess" first. That's where I came into the picture.

Turns out it was a CJ-7 and was 100% complete except for the original hard top and full doors were robbed off it by another friend of the PO's for his Jeep so it had YJ half doors and a bikini top instead. The seller knew his buddy wanted to swap the top but had no idea he actually did swap the parts already. This virtually destroyed the carpet and interior of the Jeep, (great negotiating point though), that and the Bougainvillea plant growing throughout the cab and rest of it. Only the hood and one fender were visible from the overgrown thorn bearing monster plant! I asked the home owner if I could "hack the bush back to get at the Jeep" and he said FINE DO IT, I want it all GONE! He even lent me the pruning sheers and a pole chain saw to cut it away with. 15 minutes later, there was a nice relatively unmolested original paint white CJ-7 with everything to put the motor back together in the back cargo area. I negotiated $1200 fast cash and called AAA for a flatbed home! DONE!

Over the years I made slow improvements to the CJ-7 such as replacing both factory axles with built premium axles. I cleaned the interior and installed a nice stereo, CB & ham radio. There was also a Tuffy locking console installed and new off-road lights. The Jeep had a Rancho 2 1/2" lift kit installed probably pretty close to when it was new by the shape of all the bushings and shocks. I removed that lift and installed a hybrid SOA/SUA at the time I upgraded both axles. I figured when I am ready to install the diesel engine, I wanted everything else in the Jeep to be up to the task. I rebuilt the factory tilt GM steering column, the clutch petals and booster. I also converted the Jeep to 4-wheel disc brakes when I swapped the rear axle. The front end got crossover high steering, a new thicker one-piece welded power steering bracket and heavy duty AGR rock-box. 1-ton steering by Rough-Stuff and new heavy duty lockout hubs by Mile Marker. I still had an old Super Top BesTop frame in the garage for my last trail riding YJ so I swapped that on it and bought a brand new skin with windows for it. Luckily I also had the YJ half upper wire frames so new skins for them and the doors were ready to go.

What's nice about the YJ wrangler and the CJ-7 body is dimensionally they are so similar, most of the parts interchange so I was able to use the YJ Wrangler SuperTop and factory metal YJ half doors on the CJ. Also the uppers fit great too. Even the back seat fits with minor adjustment from YJ to CJ-7!

When I did the axle swaps I also reached into my old YJ pile-O-parts that were saved and installed Pro-Comp YJ Wrangler 4" lift kit in the rear straight off the YJ and onto the CJ. They are an exact fit and still SUA out back. The shocks also fit with some mods to the mounting tabs on the new rear Ford 8.8 axle I used. Up front I used a fresh pair of stock 6-cylinder hard top heavy YJ 2.5" wide leaf springs in SOA configuration over the new GM Camper Spl Dana 44 front axle I built for the CJ. The front shocks were ordered specific for application because the YJ uses studs on top instead of eyes on both ends like the CJ does. Both axles have 4.10 gears and lockers. Front is an ARB, back has a full case Detroit and then armored covers.

I also reached again into the stack of YJ spare parts-O-plenty for the front and rear 4" lift extended SS brake lines from the YJ ProComp lift kit. They fit perfectly!

Here is where we come to The Diesel Jeep Build part and I will post photos over the next several weeks along with some photos I have from various other upgrades like the axles since all this tech is VERY similar to YJ Wranglers, just a little different.

The Jeep was originally a 4-cylinder AMC 2.5L powered T-4 4 Speed Jeep. I unbolted the motor mounts and bought M.O.R.E. V8 motor mounts for a short-lived Chevy 350 V8 TBI engine swap I had going. That came out and gave way for a 5.3L Vortec V8 Gen III gasser that was in there with another set of M.O.R.E. mounts. That engine and transmission were sold to another forum member for his TJ Wrangler and the engine bay is now EMPTY and ready for the Cummins BT engine I have in a crate. It is an ex-Frito-Lay bread/chips delivery van "Cummins Re-Power Program" fleet engine. It went almost 300K with another engine, then was removed and factory Cummins Remanufactured engine refit program motor installed. It has around 45K since the refit before retiring the van and runs great.

This Cummins motor was originally setup for a GM Allison 1000 2WD automatic but the seller was kind enough to swap the SAE to bellhousing adapter out for a Ford style and flywheel so I could use my ZF s5-42 5-speed O.D. manual. I am going to have to flip the oil pan to rear sump because it is currently front sump so I need another pickup tube.

Now I am working on the sump and cleaning up the engine to get it ready. I am also working on the engine bay and mocking up the engine mounts.

Design criteria for the mounts:

1. Support and position the powertrain with enough strength to keep the mounts from getting damaged in severe rock crawling torque use.

2. Clearance for the body and hood maintained along with positioning for drive shaft clearance.

3. Help to isolate vibrations from the powertrain while running, (recommended Cummins engineering is above the centerline of the crankshaft) to accomplish this.

4. Transmission/transfer case mount with similar criteria.

Looking into fluid filled mounts from some other widely used application to reduce cost and increase ease of sourcing the mount.

Pictures to follow of where we are at soon.... I will edit this to add more and any table of contents as time goes by with posts.

Rebuilding the D300 transfer case with a JB conversions 4:1 and 32 spline HD output shaft. This will also get a conversion input spud shaft kit for mating to the ZF s5-42 transmission at the same time.

Thanks for looking,

more to follow......

RR

Last edited: