If you own a Jeep YJ, at the time of this writing it is at least 24 years old. That’s a long time for a rig that was designed in the early 80s, when the American automotive industry was, frankly, not doing its best work. If you’re going to keep your YJ working reliably, you’re going to need to give it some love. The lighting systems are common failure points on this rig. In this article, we’ll look at how to get the turn/hazard/brake systems working and keep them that way.

System Overview

The systems we’re looking at are powered from three fuses in the Power Distribution Center under the hood:

Supply Power Checks

There are three checks to ensure that the systems are properly powered:

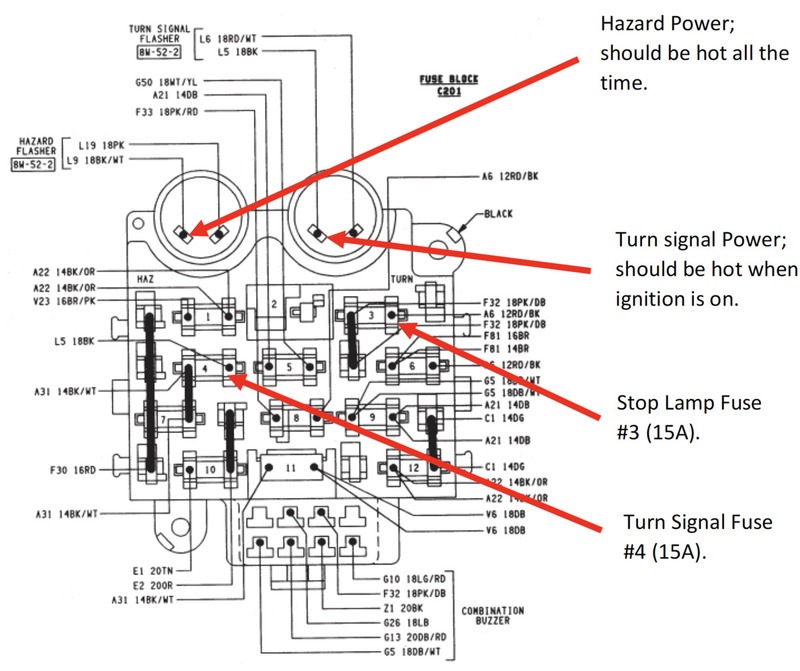

First, remove both flashers from their sockets in the fuse block. The left flasher is for the hazard circuit, and the right flasher is for the turn signals (see Figure 1). Each socket has two connectors arranged in a “V” pattern.

Visually inspect the flashers before you put them back in. If either the turn or hazard systems are not working, you can swap flashers and see if that changes which system is failing. If there’s any reason to suspect the flashers, it doesn’t hurt to replace them.

Note: Fuse 3 is labeled “Haz Stop”, but does not protect or control the hazard circuit.

Figure 1: The Fuse Block

Supply Power Fixes

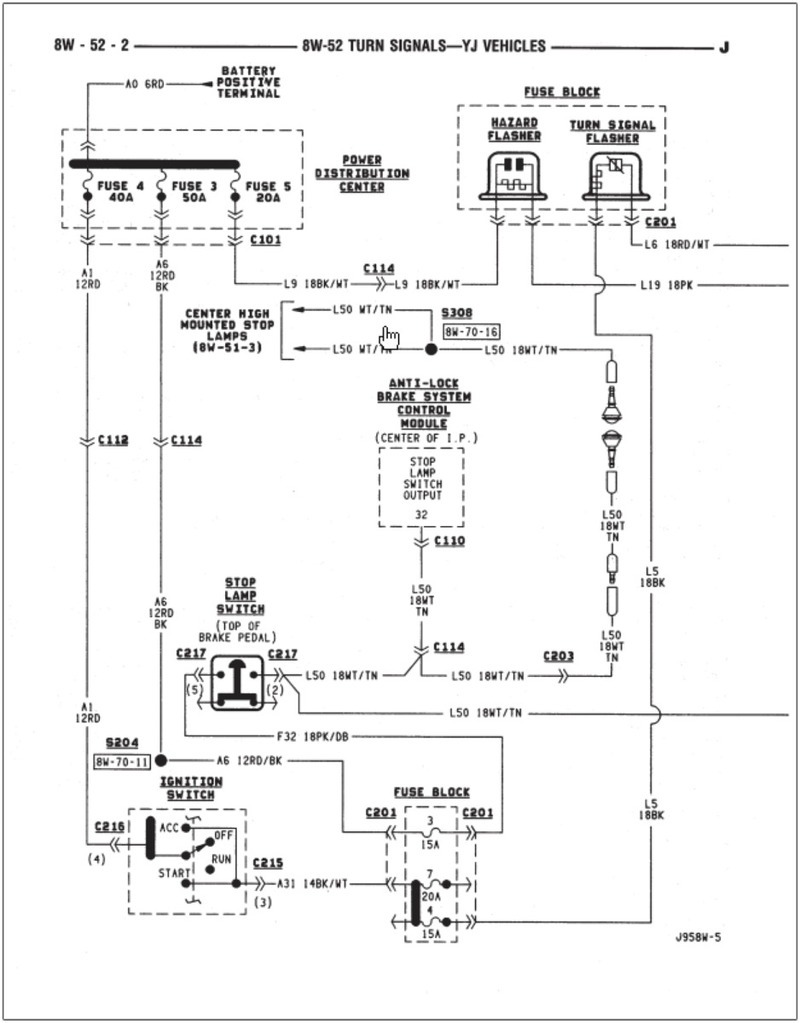

If your rig fails one of the power supply checks, the fix is to trace the circuit back to the power source (the battery), and find the component that’s causing the fault. We can reference FIGURE 2 to see what components need checking:

Figure 2: The Turn, Hazard and Brake Light Power Circuits

Figure 3: The Turn Signal Switch Connector

It’s Probably A Bad Ground

There’s good reason why you hear that phrase a lot when you’re dealing with electrical issues, and especially when it concerns old lighting systems. Using the vehicle chassis as the ground system saves a huge amount of cost and complication, but it does introduce this one issue: There are going to be potential trouble points all over the rig, and any one of them can cause a system failure. Let’s look at some common culprits…

Note: Bulbs that are corroded into their sockets like to shatter rather than come out when you try to pull them. Wear gloves!

Figure 4: The bulbs and bulb sockets in a yj weren't awesome when they were new. Age and moisture only make them worse..

Is it the Switch?

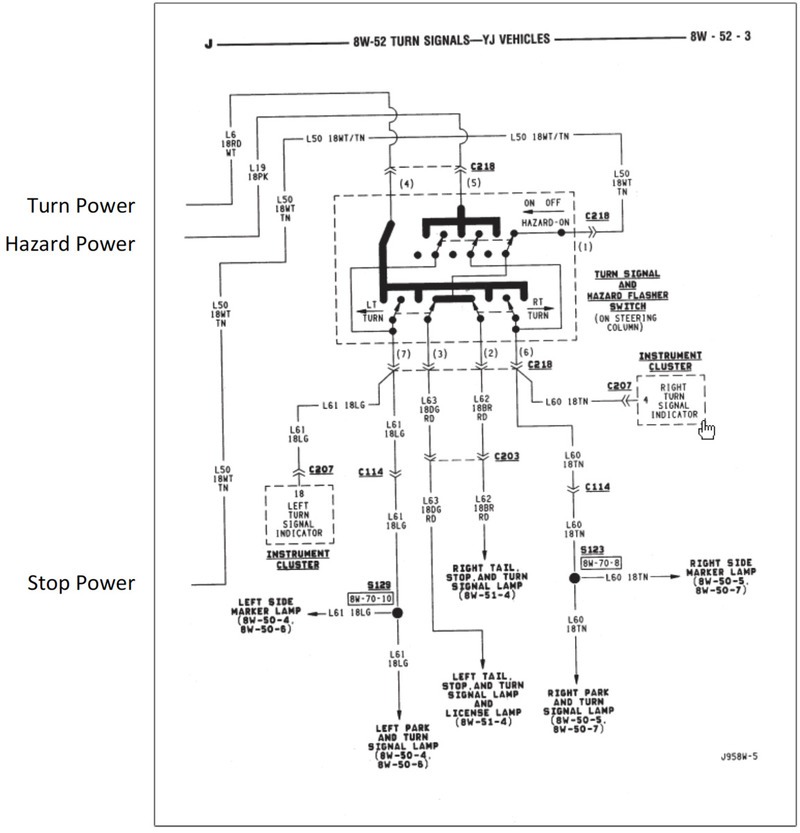

If things still aren’t working once everything is cleaned up, it’s time to figure out if the problem is the turn signal switch. By looking at FIGURE 5, we can trace the path of the current through the switch under the different circumstances.

Figure 5: The Turn Signal Switch

Brake Lights

When the turn and hazard switches are both “off”, brake light current passes directly through the turn signal switch. The input is the White/Tan wire that we checked earlier. It should be energized when the brake pedal is depressed. The output wires are:

Hazard Lights

The input wire for the hazard circuit is Pink. It is fed directly from the Power Distribution Center under the hood, through the hazard flasher. When the hazard switch is on, the following wires should have current in an intermittent, flashing pattern:

Turn Signals

The left and right turn signal switches defeat the stop light circuit for that side, allowing the other side to continue to act as a regular stop light while the active side is indicating a turn. The wires for the front and rear turn circuits are the same as for the hazard circuit. The front and rear circuits are on separate contacts in the switch, so it’s possible for one end of the rig to be working, while the other is not.

Below is the information for the various circuits, and a “truth chart” for the various functions. It’s good to check the turn signal switch thoroughly before deciding to replace it, but frankly, if you’ve gotten this far in the testing, it’s probably a bad switch.

Other Things to Check

The likely causes are checked now. The rest are long shots.

The wiring harness for the rear lights runs along the left side of the rig, under the driver’s door and up along the left bed sill. From there it dives into the left rear fender area to feed the left rear lights, and then runs to the right side between the bed and fuel tank. There are one or two connectors under the dash just in front of the driver’s door that feed that harness.

The front lighting harness also runs along the left side of the rig, coming through the main connector behind the fuse block at the firewall. If you’ve gotten this far, that connector is worth checking. Have some dielectric grease handy for putting it back together.

Wires can get pinched between metal components, cut on sharp edges, or cracked and brittle from heat or age. Sometimes a short in one circuit can cause wires in a harness to fuse together and short out. At this point the problem should be narrowed down to a specific circuit (rear left, etc). You may need to unwrap the harness and visually inspect the wires.

That’s all I’ve got. Good luck!

-Walt

System Overview

The systems we’re looking at are powered from three fuses in the Power Distribution Center under the hood:

- Fuse 3: 50 Amp, Fuse Block

- Fuse 4: 40 Amp, Ignition System

- Fuse 5: 20 Amp, Hazard Flash

- The Fuse Block (Figure 1), located under the dashboard on the left side of the rig.

- The Ignition Switch, located on top of the steering column

- The Stop Lamp Switch, mounted on the brake pedal arm

- The Turn Signal and Hazard Flashers, located at the top of the fuse block

- The Turn Signal and Hazard Flasher Switch, mounted in the steering column

- The lights themselves, mounted at the front and rear of the rig, and also in the instrument panel

Supply Power Checks

There are three checks to ensure that the systems are properly powered:

First, remove both flashers from their sockets in the fuse block. The left flasher is for the hazard circuit, and the right flasher is for the turn signals (see Figure 1). Each socket has two connectors arranged in a “V” pattern.

- For the hazard (left) flasher socket, the left connector should be energized all the time

- For the turn signal (right) flasher socket, the left connector should be energized when the ignition switch is turned on.

Visually inspect the flashers before you put them back in. If either the turn or hazard systems are not working, you can swap flashers and see if that changes which system is failing. If there’s any reason to suspect the flashers, it doesn’t hurt to replace them.

Note: Fuse 3 is labeled “Haz Stop”, but does not protect or control the hazard circuit.

Figure 1: The Fuse Block

Supply Power Fixes

If your rig fails one of the power supply checks, the fix is to trace the circuit back to the power source (the battery), and find the component that’s causing the fault. We can reference FIGURE 2 to see what components need checking:

Figure 2: The Turn, Hazard and Brake Light Power Circuits

- The hazard circuit feeds through Connector C114, directly from Fuse 5 (20 Amp) in the Power Distribution Panel.

- The turn signal circuit feeds through Fuse 4 (15 Amp) in the Fuse Block, the Ignition Switch, Connector 114, and finally through Fuse 4 (40 Amp) in the Power Distribution Panel

- The brake light circuit feeds from Fuse 3 (15 Amp) in the Fuse Block, through Connector 114 and then Fuse 3 (50 Amp) in the Power Distribution Panel

Figure 3: The Turn Signal Switch Connector

It’s Probably A Bad Ground

There’s good reason why you hear that phrase a lot when you’re dealing with electrical issues, and especially when it concerns old lighting systems. Using the vehicle chassis as the ground system saves a huge amount of cost and complication, but it does introduce this one issue: There are going to be potential trouble points all over the rig, and any one of them can cause a system failure. Let’s look at some common culprits…

- Sheet metal screw ground points. These can corrode, work loose, or the crimp connectors can fail. Keep them clean and tight.

- Component mount points. Some parts such as the YJ tail light housings bolt to the body, and that bolted connection is also a ground path. Tight and clean are the key words here as well.

- Bulb sockets (Figure 4). This is a very common failure point on older vehicles, and it can cause weird problems where various circuits start to interact (i.e. you put on your left blinker and your tail lights dim). What’s happening is a circuit has lost its regular path to ground, and is grounding through another circuit. Often, the connection point is a shared bulb socket that gets corroded, so the problem shows up a lot with the turn/stop and tail light circuits.

Note: Bulbs that are corroded into their sockets like to shatter rather than come out when you try to pull them. Wear gloves!

Figure 4: The bulbs and bulb sockets in a yj weren't awesome when they were new. Age and moisture only make them worse..

Is it the Switch?

If things still aren’t working once everything is cleaned up, it’s time to figure out if the problem is the turn signal switch. By looking at FIGURE 5, we can trace the path of the current through the switch under the different circumstances.

Figure 5: The Turn Signal Switch

Brake Lights

When the turn and hazard switches are both “off”, brake light current passes directly through the turn signal switch. The input is the White/Tan wire that we checked earlier. It should be energized when the brake pedal is depressed. The output wires are:

- Left Turn (rear): Dark Green/Red

- Right Turn (rear): Brown/Red

Hazard Lights

The input wire for the hazard circuit is Pink. It is fed directly from the Power Distribution Center under the hood, through the hazard flasher. When the hazard switch is on, the following wires should have current in an intermittent, flashing pattern:

- Left Turn (rear): Dark Green/Red

- Right Turn (rear): Brown/Red

- Left Turn (front): Light Green

- Right Turn (Front): Tan

Turn Signals

The left and right turn signal switches defeat the stop light circuit for that side, allowing the other side to continue to act as a regular stop light while the active side is indicating a turn. The wires for the front and rear turn circuits are the same as for the hazard circuit. The front and rear circuits are on separate contacts in the switch, so it’s possible for one end of the rig to be working, while the other is not.

Below is the information for the various circuits, and a “truth chart” for the various functions. It’s good to check the turn signal switch thoroughly before deciding to replace it, but frankly, if you’ve gotten this far in the testing, it’s probably a bad switch.

| Connector Terminal # | Wire Color | Description | Stop On | Hazard On | Left Turn | Right Turn |

| 1 | White / Tan | Stop V+ (From Brake Switch) | ||||

| 2 | Brown / Red | Right Rear Turn / Stop | V+ | V+ Flash | V+ Flash | |

| 3 | Dark Green / Red | Left Rear Turn / Stop | V+ | V+ Flash | V+ Flash | |

| 4 | Red / White | Turn Signal V+ (Ignition Switched/ From Flasher) | ||||

| 5 | Pink | Hazard V+ (From Flasher) | ||||

| 6 | Tan | Right Front Turn & Dash Indicator | V+ Flash | V+ Flash | ||

| 7 | Light Green | Left Front Turn & Dash Indicator | V+ Flash | V+ Flash |

Other Things to Check

The likely causes are checked now. The rest are long shots.

The wiring harness for the rear lights runs along the left side of the rig, under the driver’s door and up along the left bed sill. From there it dives into the left rear fender area to feed the left rear lights, and then runs to the right side between the bed and fuel tank. There are one or two connectors under the dash just in front of the driver’s door that feed that harness.

The front lighting harness also runs along the left side of the rig, coming through the main connector behind the fuse block at the firewall. If you’ve gotten this far, that connector is worth checking. Have some dielectric grease handy for putting it back together.

Wires can get pinched between metal components, cut on sharp edges, or cracked and brittle from heat or age. Sometimes a short in one circuit can cause wires in a harness to fuse together and short out. At this point the problem should be narrowed down to a specific circuit (rear left, etc). You may need to unwrap the harness and visually inspect the wires.

That’s all I’ve got. Good luck!

-Walt

Last edited: