Was working well. Took a ride on my property and decided to try 4 low. Had to kind of wrestle it back out when i wanted to put it back in 2 high. Ever since then no 4wd and no indicator light. Any ideas on what could have gone wrong?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4WD stopped working on 1987 YJ

- Thread starter Too old for this

- Start date

If it’s all original probably the vacuum system on the front axle. Possibly the line leading to or the diaphragm itself.Was working well. Took a ride on my property and decided to try 4 low. Had to kind of wrestle it back out when i wanted to put it back in 2 high. Ever since then no 4wd and no indicator light. Any ideas on what could have gone wrong?

Hmmm well I’ll have to start somewhere beyond lookin at it… I checked generally the Vacuum lines are in tacked and no leaks. I wonder if the mechanical linkage is ok ?…

That’s another possibility. Also the vacuum switch on the transfer case may be the problem.Hmmm well I’ll have to start somewhere beyond lookin at it… I checked generally the Vacuum lines are in tacked and no leaks. I wonder if the mechanical linkage is ok ?…

Flyer58

YJ Addict

Once the vacuum motor on the front axle connects the two halves they'll stay connected until another vacuum line moves them apart.

Shift into 4wd and check the continuity of the switch, open circuit or closed, then shift into 2wd and check it. The motor does not need to be running. Just check if the switch is making contact. Could be a burned out light too.

It doesn't take much to remove the vacuum motor to see if it's working with a vacuum.

Shift into 4wd and check the continuity of the switch, open circuit or closed, then shift into 2wd and check it. The motor does not need to be running. Just check if the switch is making contact. Could be a burned out light too.

It doesn't take much to remove the vacuum motor to see if it's working with a vacuum.

Ok thank you all but boy oh boy what a dumb mistake I made that caused the problem!… when i got the jeep i noticed some really dry, cracked and missing rubber lines and rubber vacuum caps, as this was a vehicle that saw some tough times and a few back yard mechanics. So I started changing and replacing stuff, including putting a cap on what i thought was a detached vacuum line. Turned out to be the vent and check valve for the 4wd vacuum motor you guys pointed too…very rookie mistake on my part. Thanks again for the help. Removed cap and all is wellOnce the vacuum motor on the front axle connects the two halves they'll stay connected until another vacuum line moves them apart.

Shift into 4wd and check the continuity of the switch, open circuit or closed, then shift into 2wd and check it. The motor does not need to be running. Just check if the switch is making contact. Could be a burned out light too.

It doesn't take much to remove the vacuum motor to see if it's working with a vacuum.

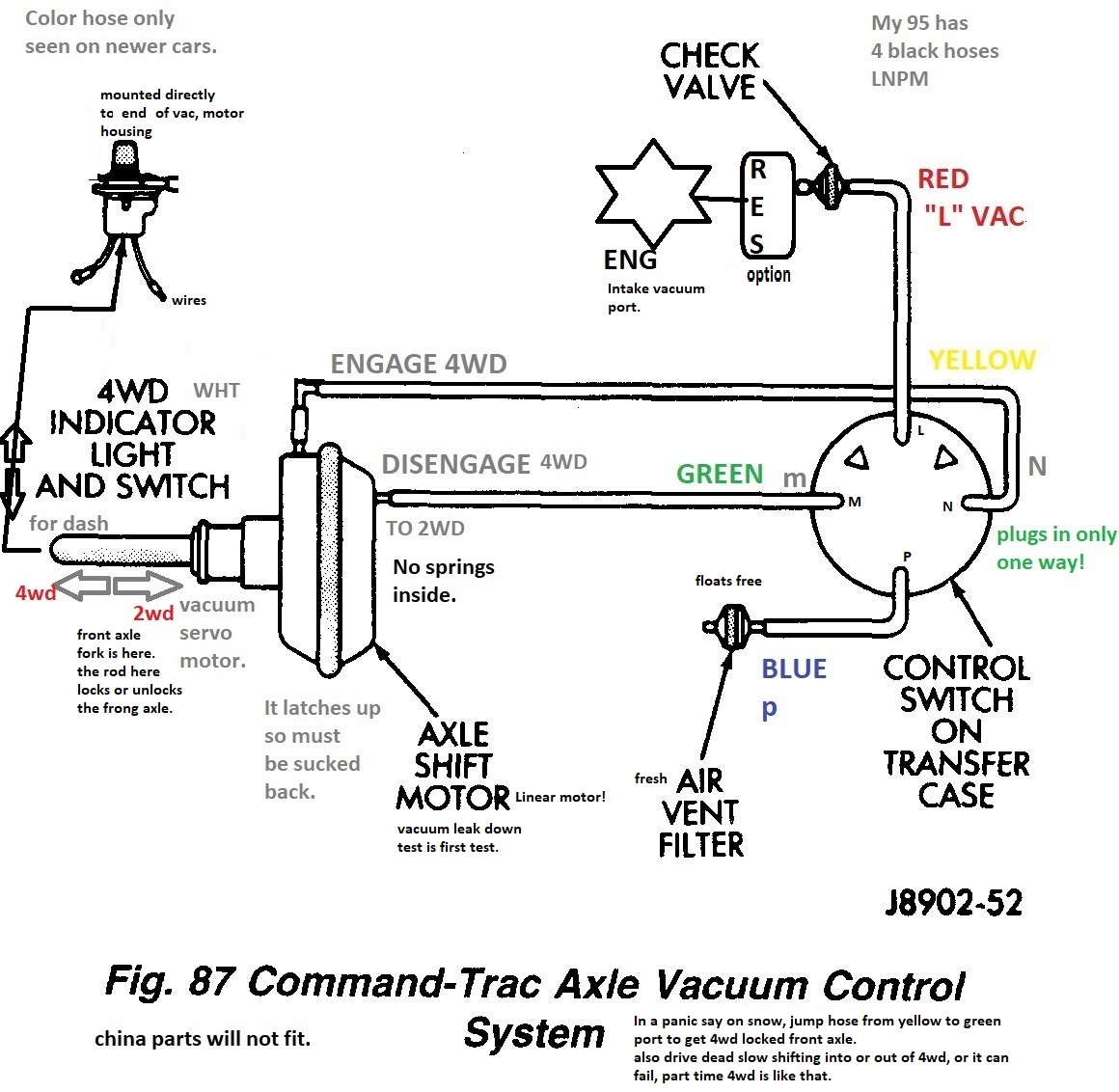

that vacuum servo (motor_ actuator) is push/ pull logic.

when one side sucks the other end vents.

if not , it goes to loggerheads. (means fights it self)

get a hand held vacuum pump,(w/gauge) and use it on the inboard nipple to get 4wd, the move to outboard ( all hoses pulled) and now 2wd and dash lamp goes off.

helps to have right wheel off ground. so the Vac servo etc can move easy

oops that free line is the VENT, oops

95 looks like this.YJ

mine crib. ( the service manual is free, ask>)? it's all covered there.

when one side sucks the other end vents.

if not , it goes to loggerheads. (means fights it self)

get a hand held vacuum pump,(w/gauge) and use it on the inboard nipple to get 4wd, the move to outboard ( all hoses pulled) and now 2wd and dash lamp goes off.

helps to have right wheel off ground. so the Vac servo etc can move easy

oops that free line is the VENT, oops

95 looks like this.YJ

mine crib. ( the service manual is free, ask>)? it's all covered there.

Last edited:

here is the 15min job test. for 4wd.

if this passes so will driving if the front of transfer case mode valve is not dead. or hoes bad or connected wrong.

in 1min work I see the diaphragm is not cracked, (std.leak down test all techs know)

then apply 15"Hg vacuum to inboard nibble right tire off the ground and i spin the tire and hear the forks lamp the coupling in 4wd lock (clank)_

and the pinion spins. now.

easy 15min work.

next key on the cluster center of dash not drivers cluster. left side lamp glows 4WD, key on or running.(tranny 5speed in neutral.

the test 4wd if fails the transfer case valve in front of it is dead. or 4wd is dead in the transfer case deep.

my video.

front axle 4wd testing

if this passes so will driving if the front of transfer case mode valve is not dead. or hoes bad or connected wrong.

in 1min work I see the diaphragm is not cracked, (std.leak down test all techs know)

then apply 15"Hg vacuum to inboard nibble right tire off the ground and i spin the tire and hear the forks lamp the coupling in 4wd lock (clank)_

and the pinion spins. now.

easy 15min work.

next key on the cluster center of dash not drivers cluster. left side lamp glows 4WD, key on or running.(tranny 5speed in neutral.

the test 4wd if fails the transfer case valve in front of it is dead. or 4wd is dead in the transfer case deep.

my video.

front axle 4wd testing

if the lamp sticks on in 4wd, and you put vacuum on the inboard nipple, Tire off the road spun! by hand) then the servo is bad or its fork is jammed 4wd.

if not jammed then the switch is bad.

If the pinion stops moving and the lamp is stuck on,keyon, then the switch is bad. seen.at the fork housing in the video.

My lamp was bad , just replaced it now, and all tests pass.

So did the video so show how easy it is to do the tests.

My vac motor looks 30 years old and I am amazed it still works.

if not jammed then the switch is bad.

If the pinion stops moving and the lamp is stuck on,keyon, then the switch is bad. seen.at the fork housing in the video.

My lamp was bad , just replaced it now, and all tests pass.

So did the video so show how easy it is to do the tests.

My vac motor looks 30 years old and I am amazed it still works.

Key off test.

on mine I used the vacuum tool, on both nipples

and spin the tire.

and I had to spin it or the Vacuum motor stalls. and after applying hand pump vacuum there as I spin it you hear a loud clunk. (at that location)

do it to both nipples 1 at a time and spin it, it must clunk both ways or the motor is bad or the fork is jammed.

the axles are spline'd and must index and if not it jams. so the tires must turn even the most slow amount to get the lock to move.

the forks must not be dry ever. 5oz lube in the fork box.

on mine I used the vacuum tool, on both nipples

and spin the tire.

and I had to spin it or the Vacuum motor stalls. and after applying hand pump vacuum there as I spin it you hear a loud clunk. (at that location)

do it to both nipples 1 at a time and spin it, it must clunk both ways or the motor is bad or the fork is jammed.

the axles are spline'd and must index and if not it jams. so the tires must turn even the most slow amount to get the lock to move.

the forks must not be dry ever. 5oz lube in the fork box.