I had a strange rust hole on the inner fender well near where the horn attaches. It was patched years ago but it didn't last.

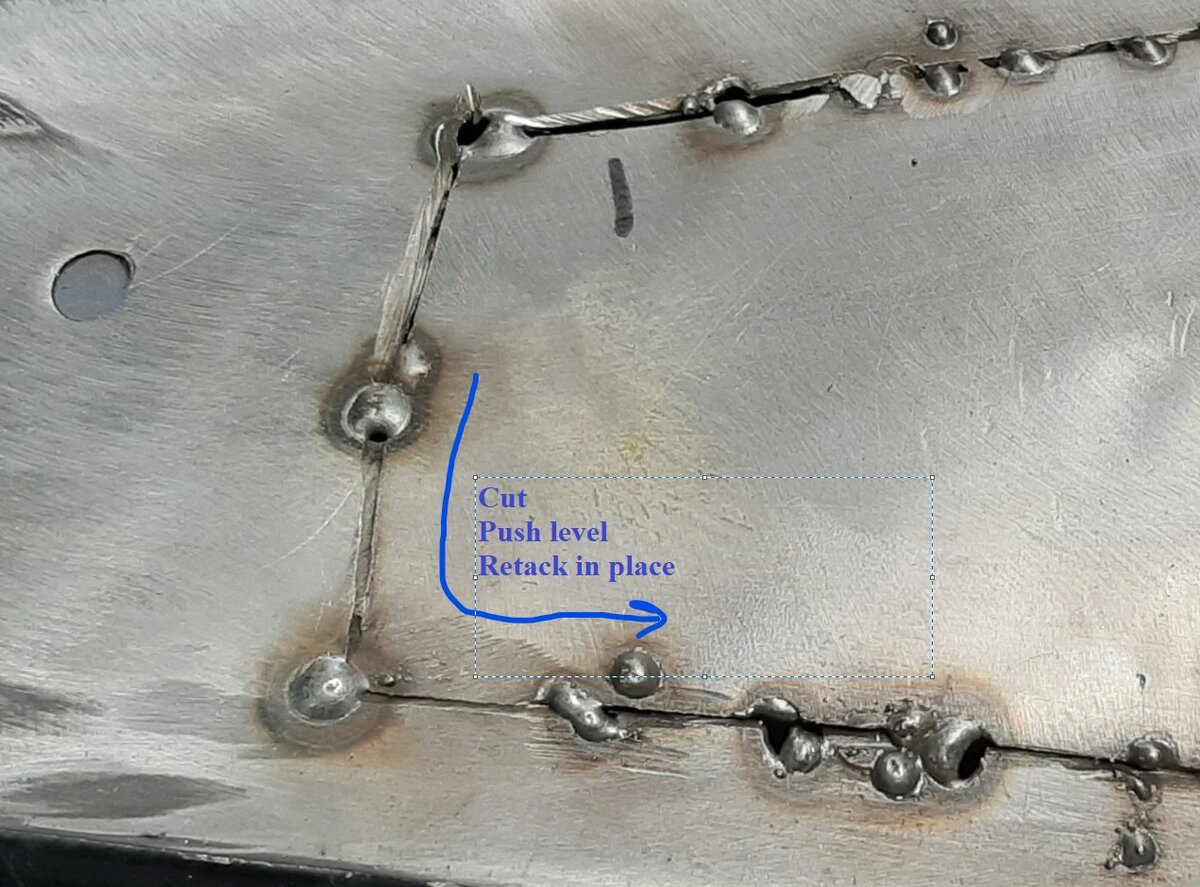

I made a paper template then cut out the patch and formed it to fit over the fender, then tack welded it in place.

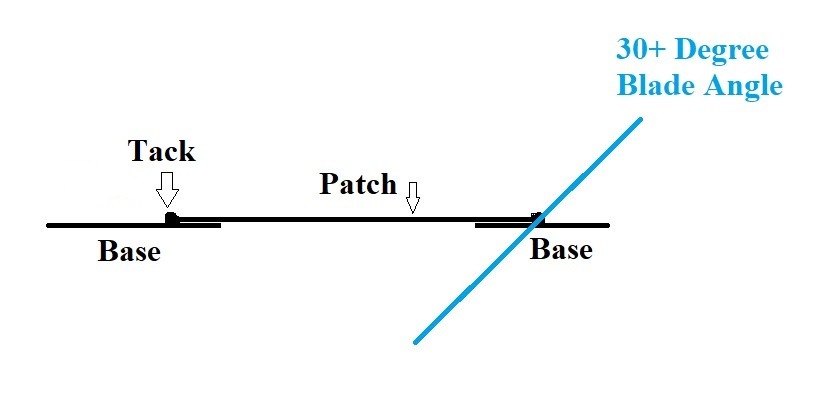

Next, while holding the cutting wheel at about a 30 degree angle I under-cut along the edge of the patch through one tack at a time, starting with a corner, and pressed the patch down level with the fender metal as I re-tacked it in place. Then continue around the perimiter. This method makes for a good narrow cut to tack into place and no additional grinding to fit.

Sanded it all level and with a touch of putty by the tacks, prime and paint and it's all good.

Rattle can Rust-Oleum for the LOL.

I made a paper template then cut out the patch and formed it to fit over the fender, then tack welded it in place.

Next, while holding the cutting wheel at about a 30 degree angle I under-cut along the edge of the patch through one tack at a time, starting with a corner, and pressed the patch down level with the fender metal as I re-tacked it in place. Then continue around the perimiter. This method makes for a good narrow cut to tack into place and no additional grinding to fit.

Sanded it all level and with a touch of putty by the tacks, prime and paint and it's all good.

Rattle can Rust-Oleum for the LOL.