It's been about six months since obtaining my '95 stock 2.5L Wrangler. I had almost new looking tires which had been sitting for over 12 years when the car was parked. They still looked new except for some slight cracking on the side walls. What is obvious is that they ended up failing within the first 1,000 miles. The 50 mph spare went on and was scary awful! I only drove it to the first tire shop I could find.

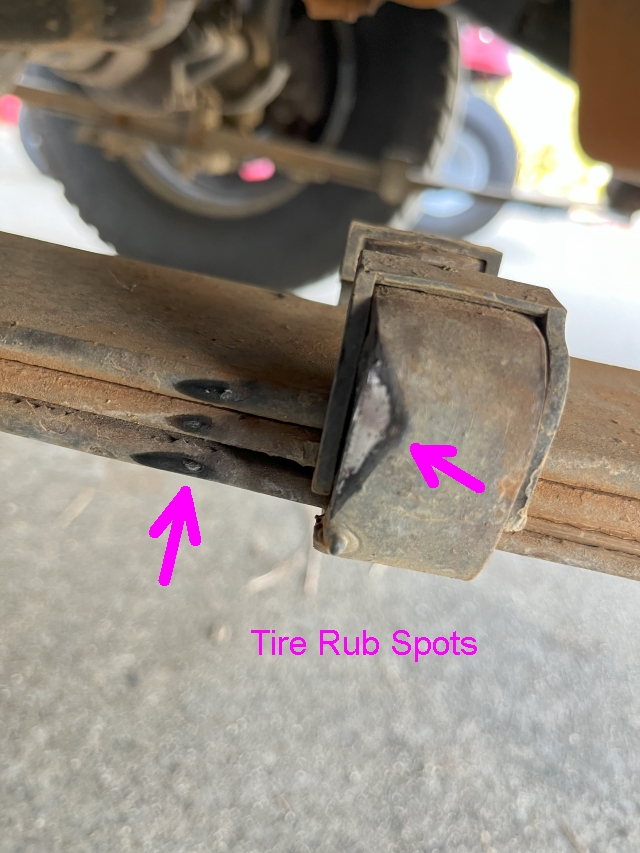

Next was the discovery that 225 tires are hard to find, have poor selection, and are expensive. So I did a switch to a slightly larger 235 tire and am happy with them. The problem I found was that when turning to get out of a tight parking spot I heard the tires scraping somewhere on the car! So today I looked into the problem and found that when turning hard both tires are able to rub against the clip holding the front spring leafs straight.

The tire shop said I should look for some offset wheels to replace the 5 Jeep ones. In looking it all over I decided that all I have to do is to back the steering stop bolts out a thread or two until the noise stops. The slight increase in turning radius is negligible. I haven't tested this out yet as I discovered something that looks a bit gooney.

The stop bolt came out easily enough, but the bolt itself looks like a 5 year old welded it up. The bolt is just that, a bolt. It has a stop nut used to keep it from loosing it's setting. The weird thing is that after it went in to place someone thought it a good idea to tack weld it! I thought for sure some d.p.o. (do Jeep owners use the term "dreaded previous owner"?) goobered up the bolt. Checking that theory I looked at the opposite side... same thing! So is this questionable practice a factory quality measure, or a shade tree mechanic aftermarket fix?

Right now I am trying to decide: Fix 1) Add a washer or two under the welded on nut. Or Fix 2) Get a new bolt and nut, Install it and adjust stop position, then tighten lock nut down in place.

What's your vote or alternative?

Next was the discovery that 225 tires are hard to find, have poor selection, and are expensive. So I did a switch to a slightly larger 235 tire and am happy with them. The problem I found was that when turning to get out of a tight parking spot I heard the tires scraping somewhere on the car! So today I looked into the problem and found that when turning hard both tires are able to rub against the clip holding the front spring leafs straight.

The tire shop said I should look for some offset wheels to replace the 5 Jeep ones. In looking it all over I decided that all I have to do is to back the steering stop bolts out a thread or two until the noise stops. The slight increase in turning radius is negligible. I haven't tested this out yet as I discovered something that looks a bit gooney.

The stop bolt came out easily enough, but the bolt itself looks like a 5 year old welded it up. The bolt is just that, a bolt. It has a stop nut used to keep it from loosing it's setting. The weird thing is that after it went in to place someone thought it a good idea to tack weld it! I thought for sure some d.p.o. (do Jeep owners use the term "dreaded previous owner"?) goobered up the bolt. Checking that theory I looked at the opposite side... same thing! So is this questionable practice a factory quality measure, or a shade tree mechanic aftermarket fix?

Right now I am trying to decide: Fix 1) Add a washer or two under the welded on nut. Or Fix 2) Get a new bolt and nut, Install it and adjust stop position, then tighten lock nut down in place.

What's your vote or alternative?

Last edited: