This is on my '89 YJ.

Thursday's," To Do List" was replaced the fuel pump, (one on the jeep is old looking n rusty,), new Carter Carb.

No issues with it, but, figured, New tank sending unit, new carb, might as well do old looking pump! Now fuel system is all new, no issues for long time!!!

I could only find a , "Delphi", with inlet in front, ( that's what's on there now, inlet in front).

Unbolted and pulled out. New one SLIPPED right in, ( no pushing up on pump to compress arm as you bolt it in.

" Hmmmmmm, that's weird"??????

Hook up lines, crank motor, its pushing fuel out!

Replace carb, fuel filter, and fire up. Nice!!!!!

Trip @ block, short run up highway...... Good!

Next morning fire it up, electric choke issues to iron out, but, started, head to work.

3 blocks away, dies!!!!!

No fuel in carb??!!

Take filler cap off tank, bang carb, fires up. " NOW WHAT"?????!!!!!

Run it home, hop on bike, head to work.

Yesterday,( Friday), was try to set choke, no issues with pump idling in yard????????

I noticed if I put my hand on metal line from pump to filter, I could feel a vibration like pump REALLY banging away?

" Funny don't remember old one being like that"????

This morning, for sh**** and giggles, drop pump. ( they gave me like 4 gaskets, usually I get 0)!

Yanked it out, looked at pump arms.

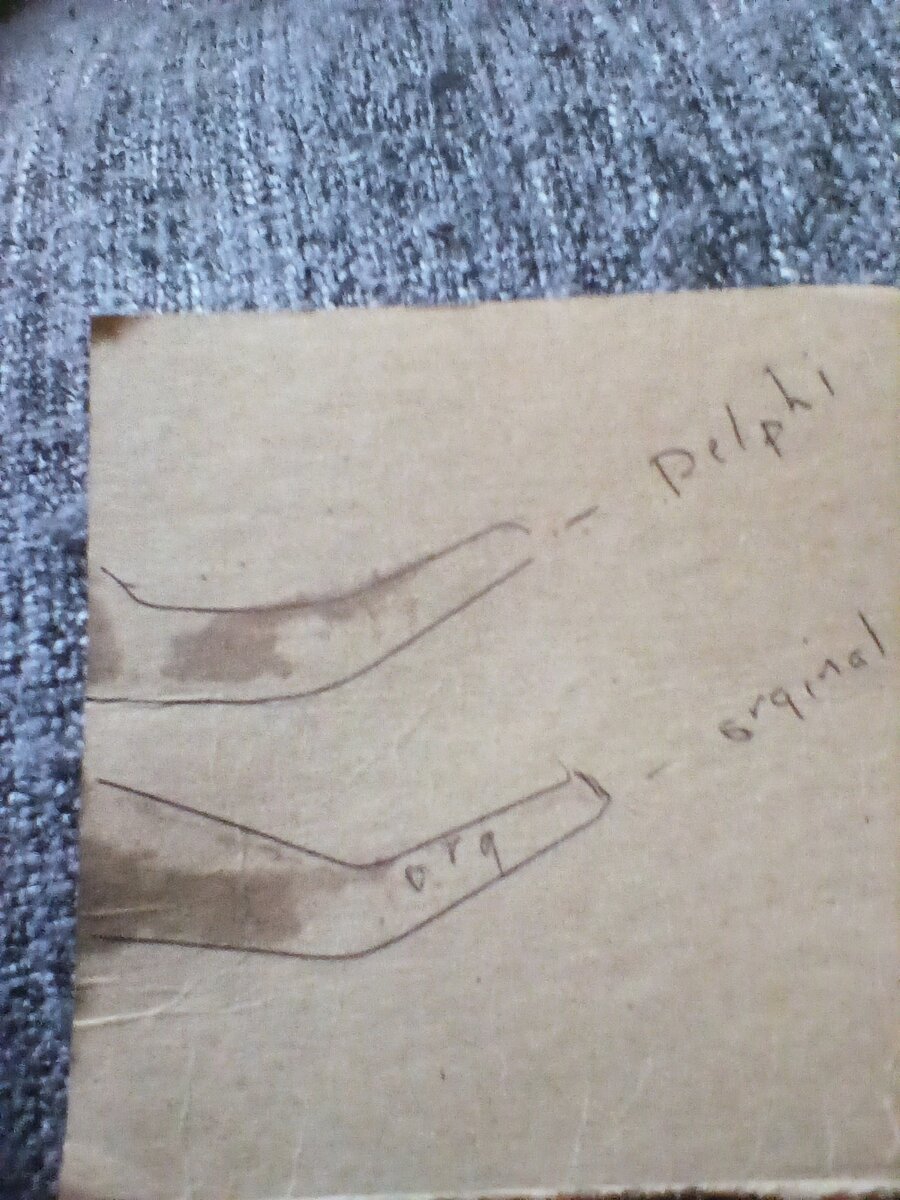

Old one and this one WAY different bend in arms ( see pics). I don't think this was resting on cam lobe, hence the banging vibration.

Put old one in, fired it up, no vibration at line, order another pump ( this one has inlet in rear, but, pump arm looks same in pic).

Any reason for this issue?

Is this '89 supposed to have inlet in rear of pump?

I hate replacing a part and creating problems like thus!!!!!!

This Jeep is 1 step forward, 2 back!

Joe

Thursday's," To Do List" was replaced the fuel pump, (one on the jeep is old looking n rusty,), new Carter Carb.

No issues with it, but, figured, New tank sending unit, new carb, might as well do old looking pump! Now fuel system is all new, no issues for long time!!!

I could only find a , "Delphi", with inlet in front, ( that's what's on there now, inlet in front).

Unbolted and pulled out. New one SLIPPED right in, ( no pushing up on pump to compress arm as you bolt it in.

" Hmmmmmm, that's weird"??????

Hook up lines, crank motor, its pushing fuel out!

Replace carb, fuel filter, and fire up. Nice!!!!!

Trip @ block, short run up highway...... Good!

Next morning fire it up, electric choke issues to iron out, but, started, head to work.

3 blocks away, dies!!!!!

No fuel in carb??!!

Take filler cap off tank, bang carb, fires up. " NOW WHAT"?????!!!!!

Run it home, hop on bike, head to work.

Yesterday,( Friday), was try to set choke, no issues with pump idling in yard????????

I noticed if I put my hand on metal line from pump to filter, I could feel a vibration like pump REALLY banging away?

" Funny don't remember old one being like that"????

This morning, for sh**** and giggles, drop pump. ( they gave me like 4 gaskets, usually I get 0)!

Yanked it out, looked at pump arms.

Old one and this one WAY different bend in arms ( see pics). I don't think this was resting on cam lobe, hence the banging vibration.

Put old one in, fired it up, no vibration at line, order another pump ( this one has inlet in rear, but, pump arm looks same in pic).

Any reason for this issue?

Is this '89 supposed to have inlet in rear of pump?

I hate replacing a part and creating problems like thus!!!!!!

This Jeep is 1 step forward, 2 back!

Joe

Last edited: