How much do you think this engine swap will cost you once it's all said and done?

I keep hearing good things about some of the V6 swaps, but part of me is tempted to go V8. Is there a reason you're going with a V6 over a V8? I'm genuinely curious.

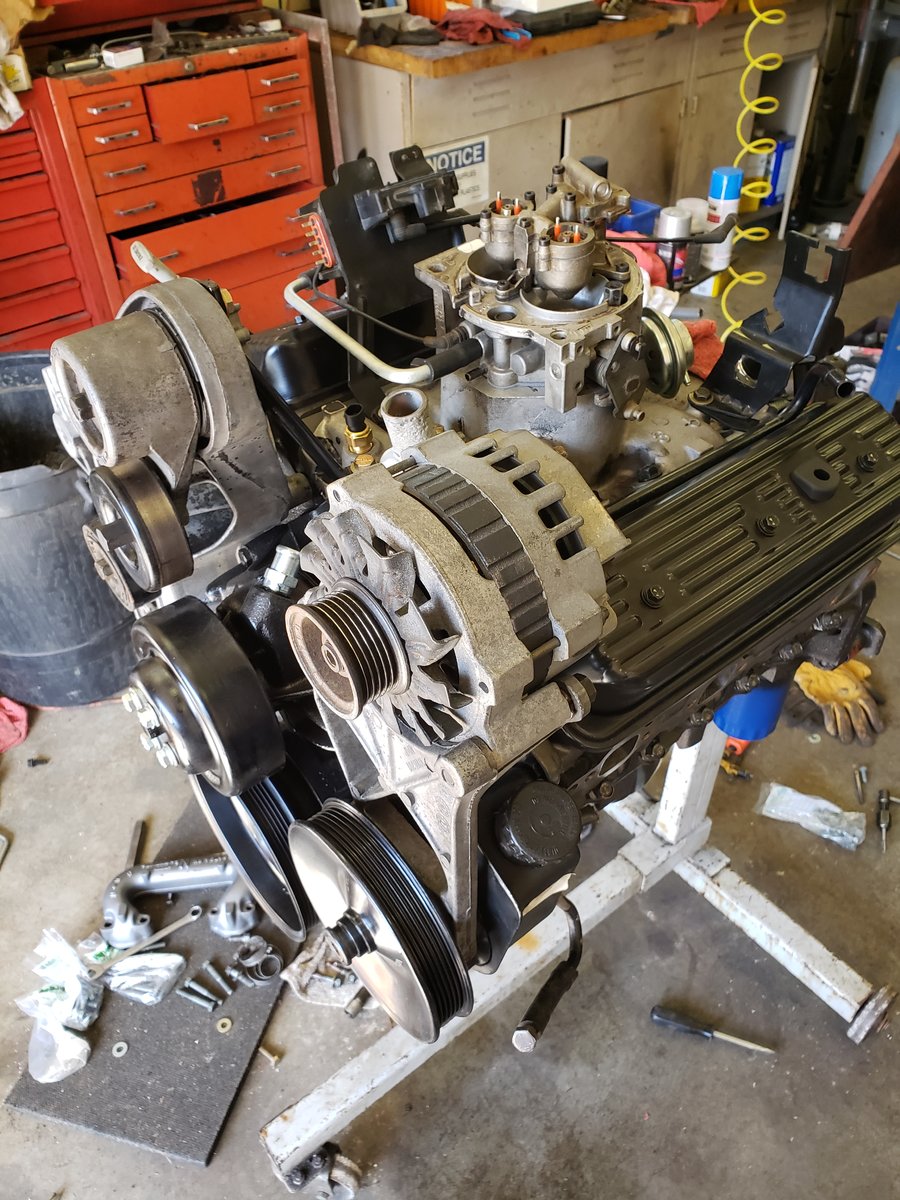

It was a tough decision. On the downside, the 4.3s are all really long in the tooth these days (but then, so am I <g>). That drives the cost/effort up if you're trying to make it nice. All the rubber parts are rotten. All the metal parts are corroded, worn, rusty, caked with 30 years of grime, or all of the above. The replaceable items (sensors, etc.) all need replacing...and you can get cheap knock-offs or pay 3X the money for the AC-Delco version. To say this thing has nickle and dimed me doesn't quite do it justice. A newer engine is more expensive to start with, of course, but it's components still have life in them, and you can just slap it in and go.

Here are the factors that steered me to the 4.3 V6...

- I've got a lot of experience with these engines, and GM engines of that era in general.

- I don't need the extra power (or weight), and didn't want to change my rear axle and radiator.

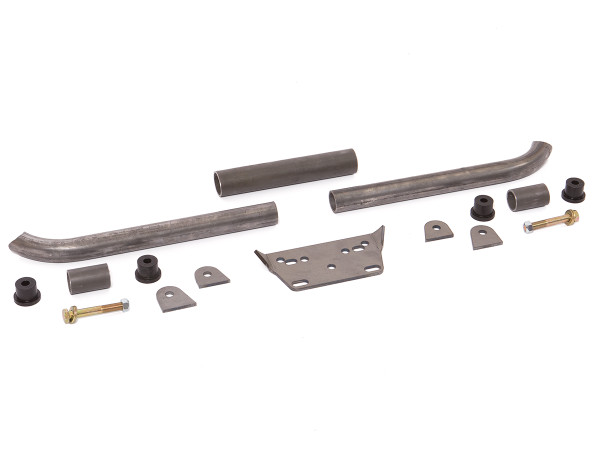

- The 91 S10 Blazer I got for a doner rig has a NP241C transfer case that's nearly identical to the NP231J in my yj. I transferred the vacuum switch and shifter lever, and as long as I position it in the same place as the old one, the drivelines and shifter linkage should work without much tweaking.

- I like the simplicity of the 700R4 transmission. At least 50% of the motivation for this swap was to get the 4 speed tranny for more comfortable highway cruising. The newer ones are all computer controlled, and while I can handle that, it adds complexity. My rig's theme is kind of rat-roddy; I wanted to keep it simple.

- Folks dropping in the newer LS engines are having all kinds of challenges getting stuff like the gauges (all computer controlled), the drive-by-wire throttle, and the baked in anti-theft stuff working right. It's all solvable, but again, I wanted simplicity.

As for overall cost... I don't want to think about it <g>. Not including the transmission rebuild, I'll easily be into this for $3500 by the time I'm done. But I did a complete rebuild on the engine. It will get a new exhaust system, etc; my goal was to create a reliable, old school rig that I could road trip with confidence. Ultimately I want to be able to drive it to Northern California with my wife, run the Rubicon trail, and drive it home.

But yeah, you never think about all the hidden expenses. The special zinc-added break-in oil that I'm going to run for just 500 miles and then change out? $80.

A lot of folks will disagree with my choices on this project, and that's fine. This rig and I will be a perfect match when it's done, and I plan to drive it until I can't drive anymore. it will be more than worth it to me.

Cheers,

Walt